Home > Material Supply > Stononlead™

Stononlead®

Stononlead® is the brand registered by Sunny Process in 2006. It complies with environmental standard of RoHS, PFOA, PFOS, and it is halogen-free as well. Because of its high temperature resistance and longer service life characteristics, mainly applied in the electronic assembly high temperature electronic process and equipment heat-insulation engineering.

Since its development in 2003, has successfully won the certification of the electronic assembly high temperature process industry, Stononlead® nowadays has become synonymous with high-efficiency materials in the carrier industry.

In order to reduce the cost of materials, expand the level of application and improve the manufacturing efficiency for users ;

Through the testing of different industries such as equipment manufacturing and machining, it is found that it can partially replace the use of synthetic stone and PEEK, and it is a high-efficiency material of high value added. The promotion is now being strengthened.

Since its development in 2003, has successfully won the certification of the electronic assembly high temperature process industry, Stononlead® nowadays has become synonymous with high-efficiency materials in the carrier industry.

In order to reduce the cost of materials, expand the level of application and improve the manufacturing efficiency for users ;

Through the testing of different industries such as equipment manufacturing and machining, it is found that it can partially replace the use of synthetic stone and PEEK, and it is a high-efficiency material of high value added. The promotion is now being strengthened.

< Stononlead® is a proprietary brand of Sunny Process Co., Ltd. Any counterfeiting will be prosecuted. >

Advantages:

- Anti-Flux.

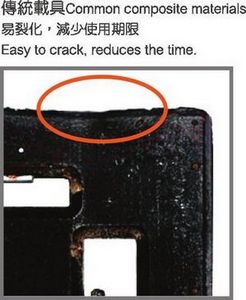

- Longer service life.

- Easier for maintenance.

- Burr-free.

- Itch-free.

Description:

- With the capacity of resistance against high temperature up to 300℃, compliance with the requirements of lead-free process.

- It resists against the erosion of Flux during the lead-free manufacturing process.

- Higher cohesion brings higher impact strength, to extend the service life of the Carrier.

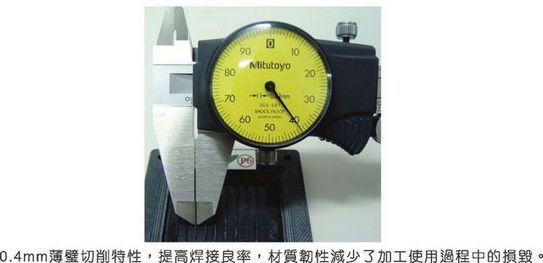

- Satisfactory properties for thin-wall finishing. Lower damage rate during the tapping process.

- Easier for cutting to reduce the service cost of the Tool.

- Lower burr rate to elevate production efficiency.

|

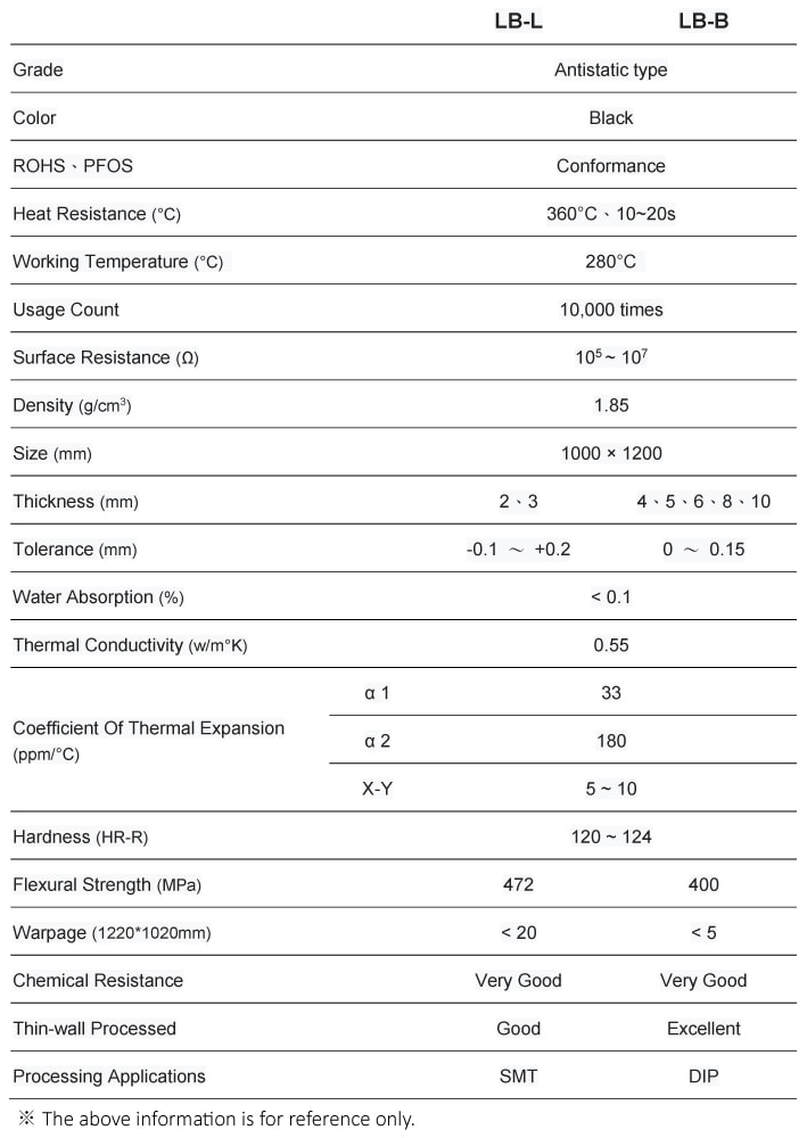

Features

|

| ||||||

|

Warpage

|

| ||||||

Thickness (mm) |

2T |

3T |

4T |

5T |

6T |

8T |

10T |

Warpage rate |

≤ 1.0% |

≤ 0.8% |

≤ 0.5% |

≤ 0.4% |

≤ 0.4% |

≤ 0.3% |

≤ 0.2% |

Warpage (1020x1220mm) |

≤ 12mm |

≤ 9mm |

≤ 6mm |

≤ 4mm |

≤ 3.5mm |

≤ 3mm |

≤ 2mm |

※ The measurement of warpage The gap of the sample on the surface plate.

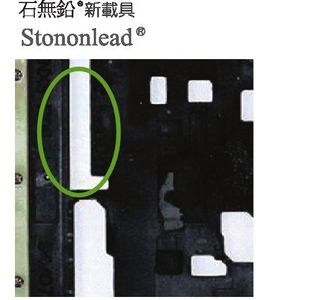

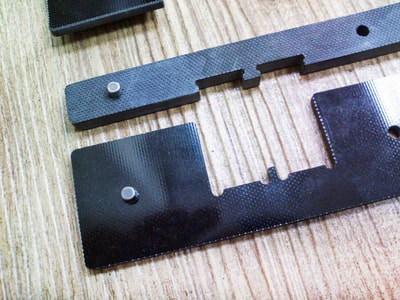

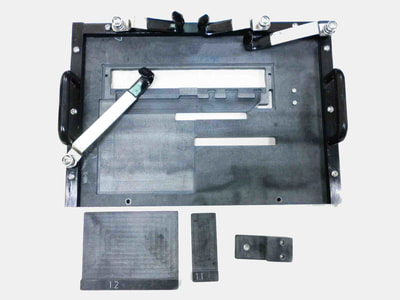

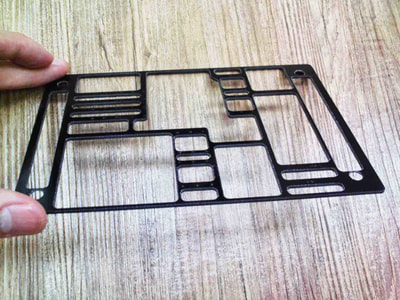

Authentic Stononlead® easier for identification

|

Each piece of Stononlead® is tagged with a serial number sticker. The user can identify whether or not it is an authentic Stononlead® with such< Stononlead® label>.

| |||||||

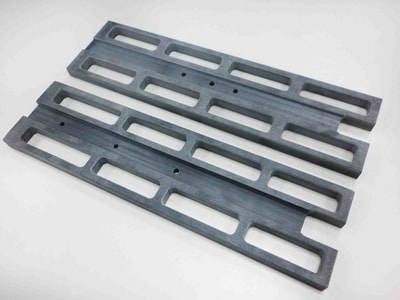

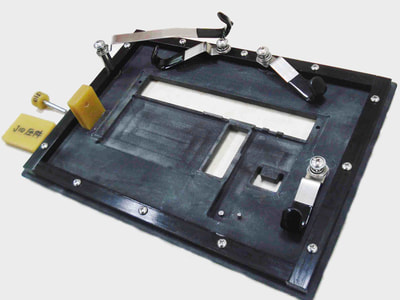

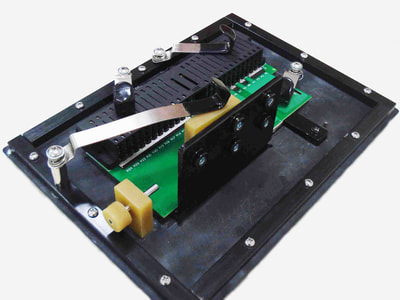

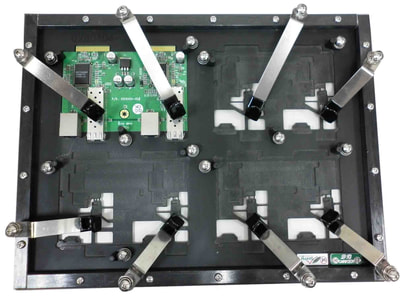

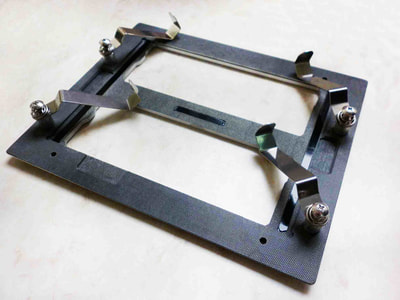

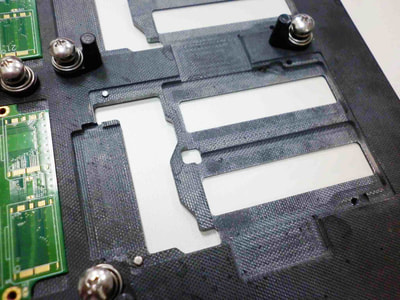

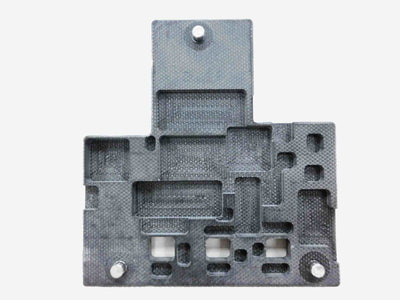

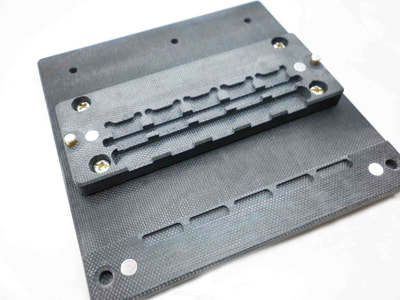

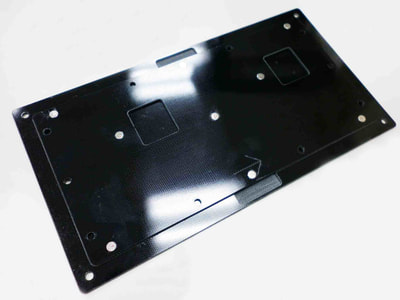

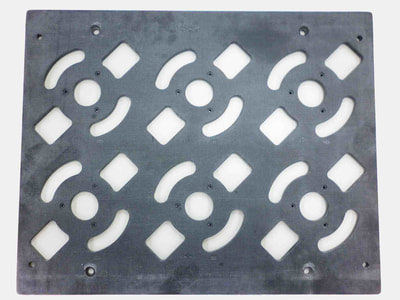

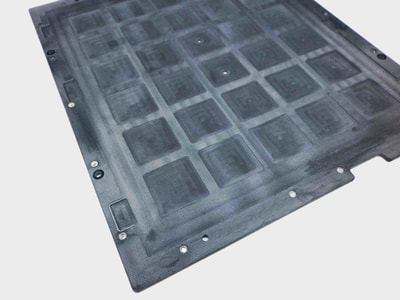

Applications

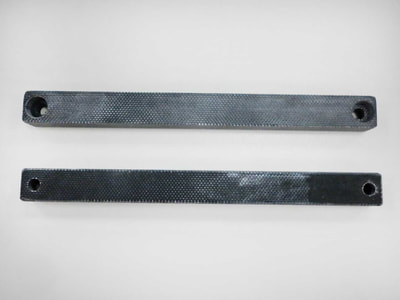

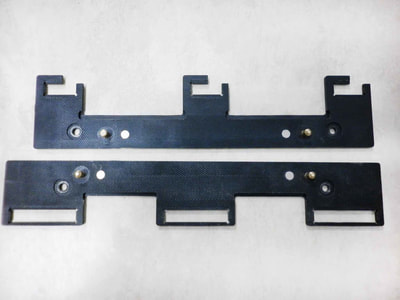

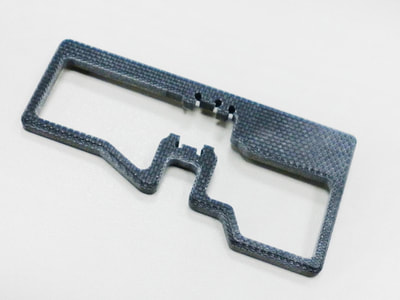

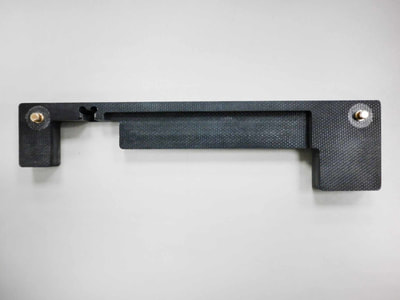

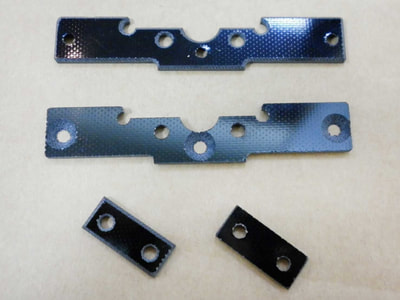

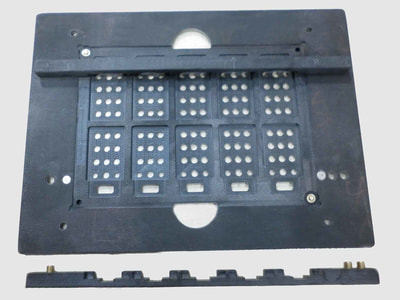

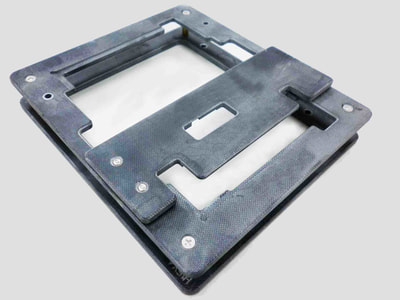

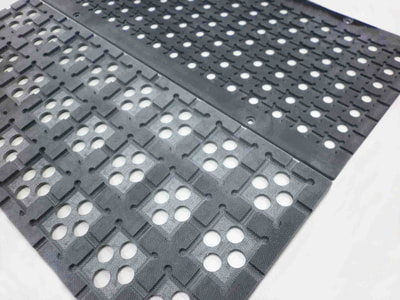

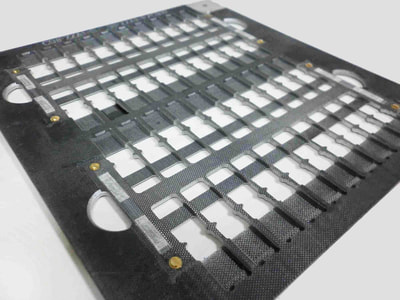

Parts Processing

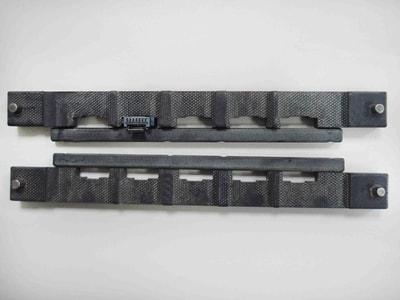

Carrier / Fixture