Comparison between Stononlead® and synthetic stone |

Item:

- Surface resistivity value

- Production defect-free rate of thin-wall cutting

- Cutting dust and residual burrs

- wear and tear of tools

- Weight loss on heating

- Structure of materials

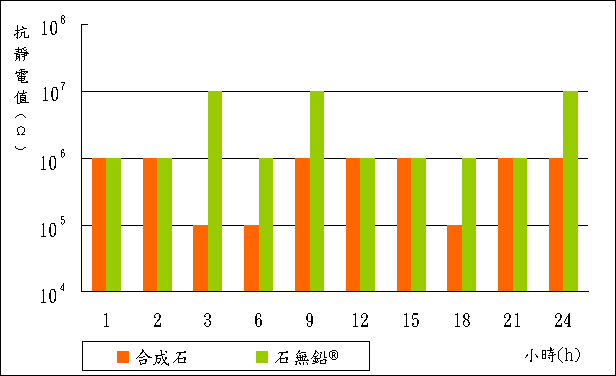

1. Surfacr resistivity value

surface resistivity value after 24 hours heating under 270℃

surface resistivity value after 24 hours heating under 270℃

- Stononlead™:10E6 ~ 10E9 Ω

- Synthetic stone:10E5 ~ 10E8 Ω

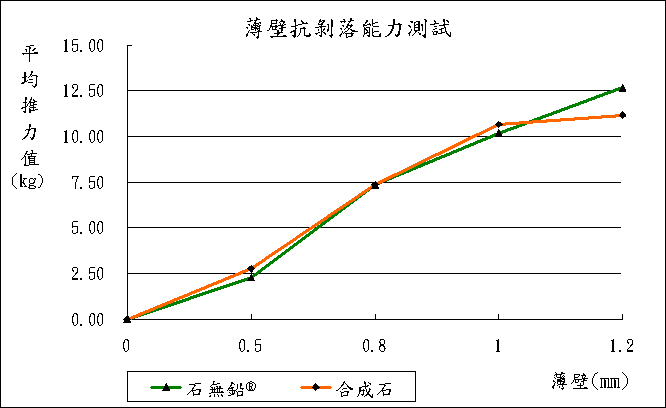

2. Production defect-free rate of thin-wall cutting

The superior performance of Stononlead™ thin wall can improve the production defect-free rate of the Carrier manufacturing and thus achieve a longer service life of production line.

- Stononlead™:99.48%

- Synthetic stone:96.53%

The superior performance of Stononlead™ thin wall can improve the production defect-free rate of the Carrier manufacturing and thus achieve a longer service life of production line.

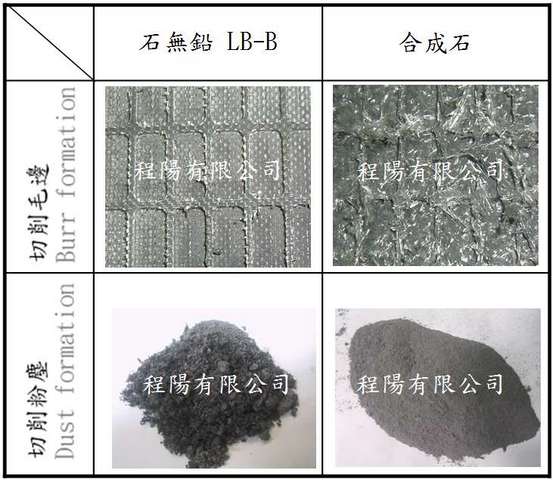

3. Cutting dust and residual burrs

After being processed, higher production efficiency can be achieved with less cutting burrs.

From the figure below, we can see that less residual Stononlead™ is experienced and it would be much easier for the finishing work during the post-treatment process to improve the product quality. Less dust will be produced during the cutting process and is less harmful to the health of the operator.

Further, it not only requires lower maintenance cost for the cutting tool and equipment but is also easier for equipment cleaning and maintenance.

After being processed, higher production efficiency can be achieved with less cutting burrs.

From the figure below, we can see that less residual Stononlead™ is experienced and it would be much easier for the finishing work during the post-treatment process to improve the product quality. Less dust will be produced during the cutting process and is less harmful to the health of the operator.

Further, it not only requires lower maintenance cost for the cutting tool and equipment but is also easier for equipment cleaning and maintenance.

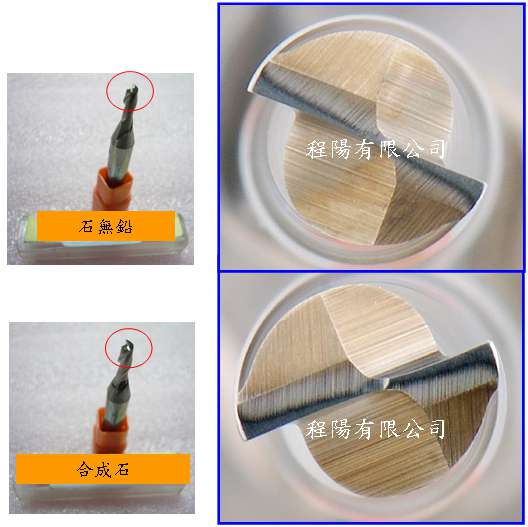

4. Wear and tear of tools

Described below is the comparison of wear and tear between all kinds of materials after the cutting process:

Described below is the comparison of wear and tear between all kinds of materials after the cutting process:

- Cutting condition:5000rpm.

- Feed rate:900mm/min .

- Tool:3mm tungsten milling tool.

- Continuous cutting:90 min.

- Under same cutting conditions, the Stononlead™ is able to reduce the tool wear and tear by over 30%.

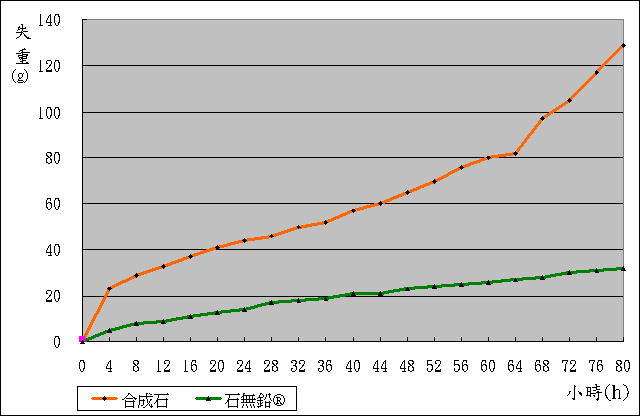

5. Weight loss on heating

Indicated in the figure below, the figures measured during 80 hours of continuous heating process under 280℃. It indicated that the weight loss of Stononlead™ is small, and the smooth curve also justifies the high stability properties of this material.

Indicated in the figure below, the figures measured during 80 hours of continuous heating process under 280℃. It indicated that the weight loss of Stononlead™ is small, and the smooth curve also justifies the high stability properties of this material.

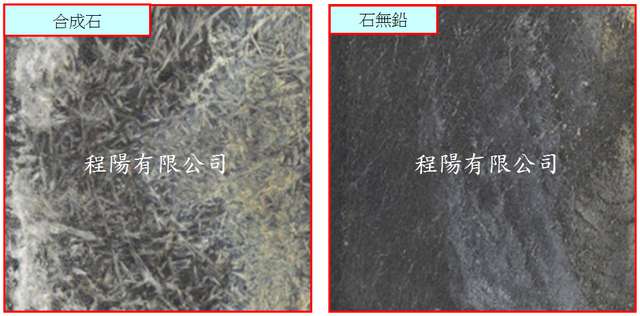

6. Structure of materials

After being used for a longer time, the synthetic stone tends to present a peeling phenomenon; but this is not seen for Stononlead™.

After being used for a longer time, the synthetic stone tends to present a peeling phenomenon; but this is not seen for Stononlead™.

Carrier service life: Results after testing the soldering oven for 10,000 times.

※ The above information is for reference only.