Home > SUNTABA vacuum pallets applications > Semiconductor Packaging Process

Snake Scale Tech -- for semiconductor packaging processes and applications

「SUNTABA vacuum pallets」complies with SGS's RoHS 2.0, PFOS, PFOA, and halogen-free environmental testing standards.

|

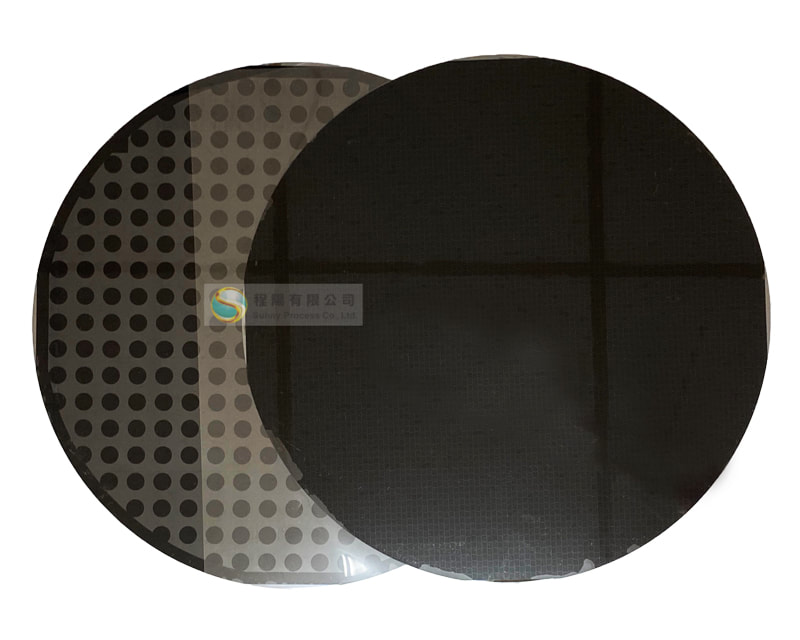

Sunny Process has developed a new type of packaging carrier through its own research and development technology, which is a new product suitable for IC or wafer packaging processes. Through the design of thin and light carriers and vacuum adsorption, the production can be carried out by simple placement and printing equipment or roller pressing without the use of metal cover plates, heat resistant tapes or magnet suction plates.

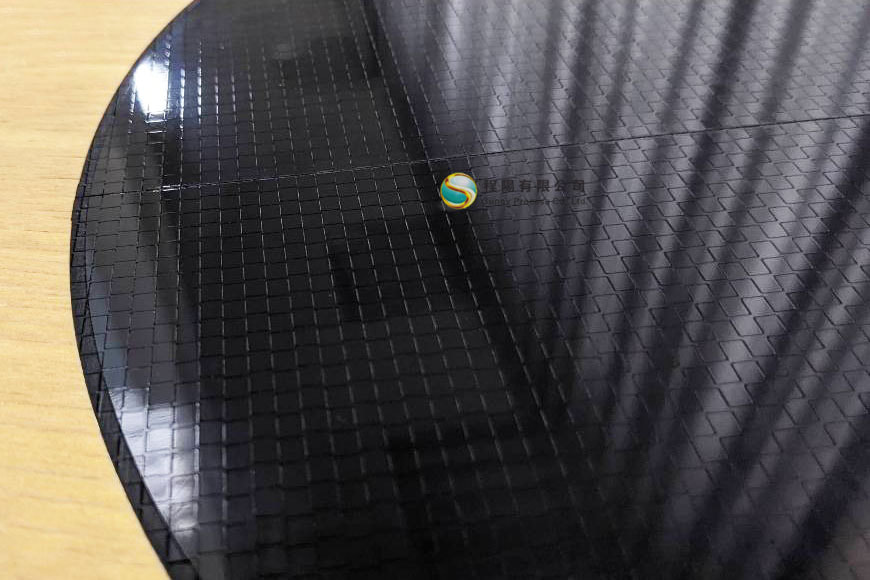

Through the principle of vacuum adsorption, when fixing IC carriers or wafers for printing, placement (SMT or diebond), wirebond, washing, molding, dispensing, curing, etc., it can prevent displacement, thermal expansion and deformation of carriers or wafers, misalignment of precision soldering, wirebond parts displacement resulting in production line interruption and flat adhesion during flux and washing. It is a carrier used in one-stop production processes. It is a revolutionary invention that can help the packaging process, which is becoming thinner and thinner, to improve packaging yields, simplify production steps, save costs, and simplify management, which is why it is aptly named 「Snake Scale Tech」. |

Snake Scale Tech Description

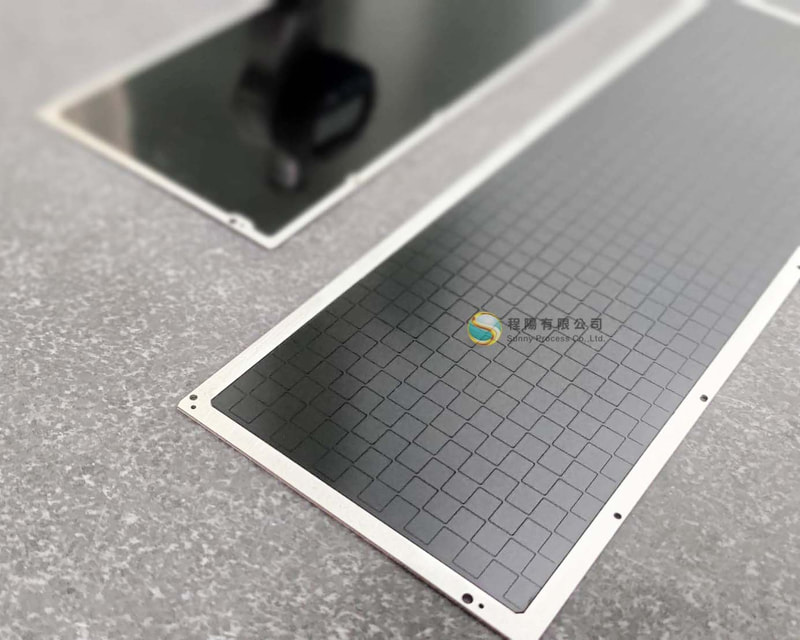

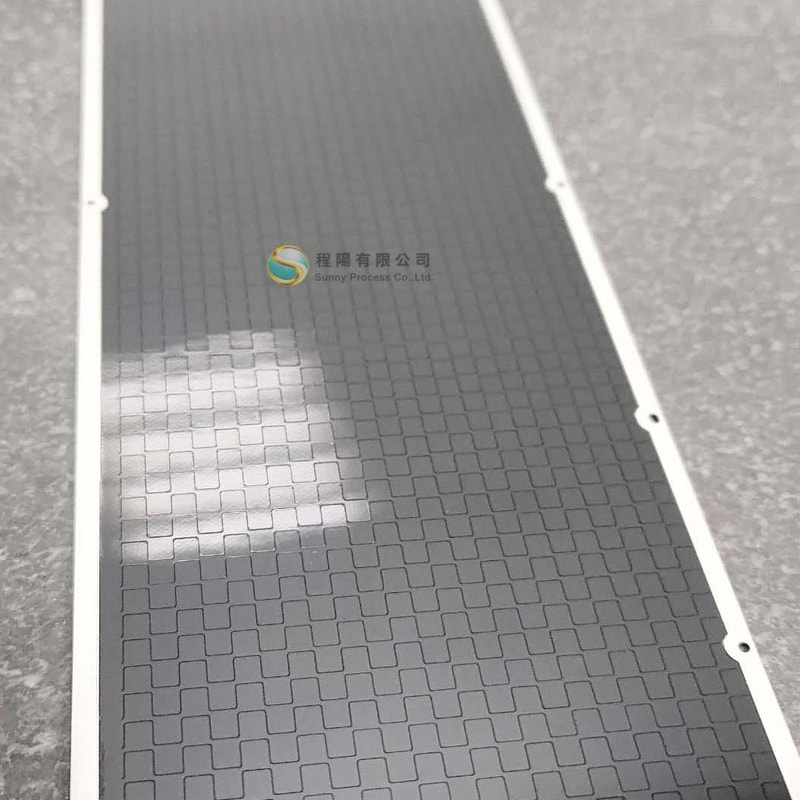

The combination of Snake Scale tech on the SUNTABA products eliminates air packing problems, maintains vacuum adsorption capability, and provides air pressure through the air holes, allowing for easy removal of thin substrates, no deformation, and full flattening for packaging process production. Relative to the packaging carriers, it can:

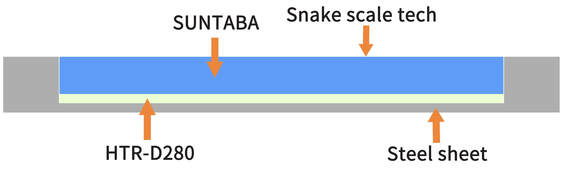

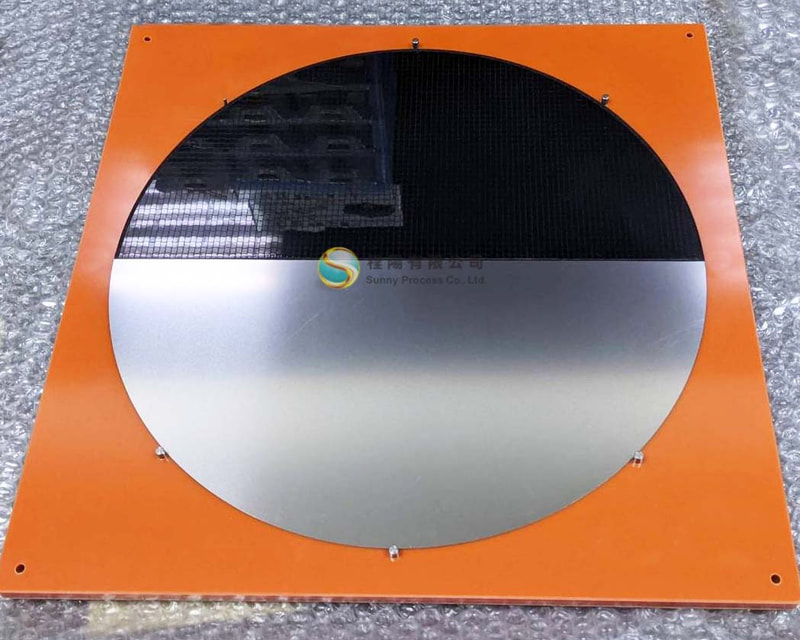

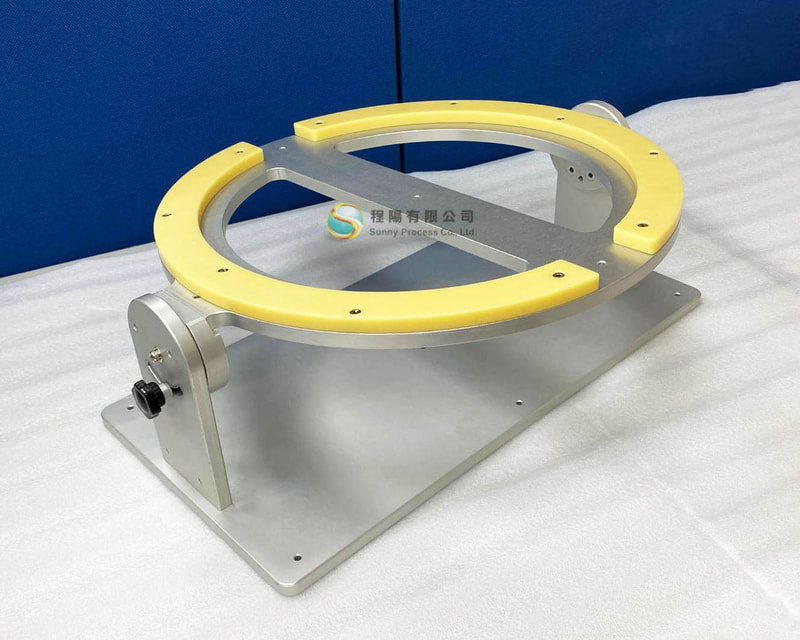

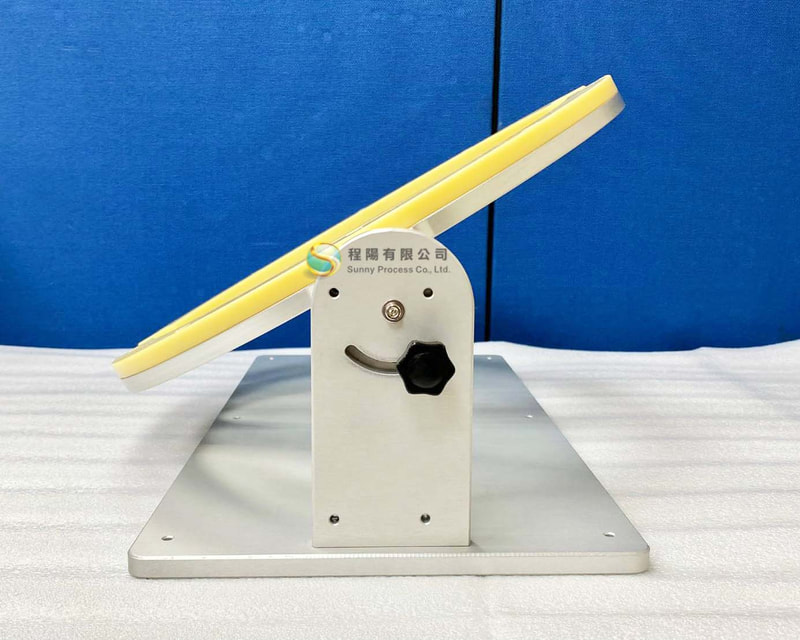

SUNTABA vacuum pallets with Snake Scale Tech applications fixture structure.

- Become thinner by 650um.

- Flatter vacuum adsorption.

- Heat resistant up to 260°C

- Reusable and long-lasting.

- Resistant to mold modding pressure.

- Low dust and washable.

SUNTABA vacuum pallets with Snake Scale Tech applications fixture structure.

SUNTABA ACID AND ALKALI RESISTANCE TEST

DIP TIME:1 HR

CHEMICAL |

CONC. |

TEMP |

RESULT |

KOH |

1% |

R.T |

OK |

Na2CO3 |

1% |

R.T |

OK |

NaOH |

1% |

R.T |

OK |

NaOH |

5% |

R.T |

OK |

NaOH |

5% |

50℃ |

OK |

FeCl3 |

- |

R.T |

OK |

FeCl3 |

- |

50℃ |

OK |

CuCl2 |

- |

R.T |

OK |

CuCl2 |

- |

50℃ |

OK |

HCl + H2O2 |

30% / 30% |

R.T |

OK |

Ti etching |

5% |

R.T |

OK |