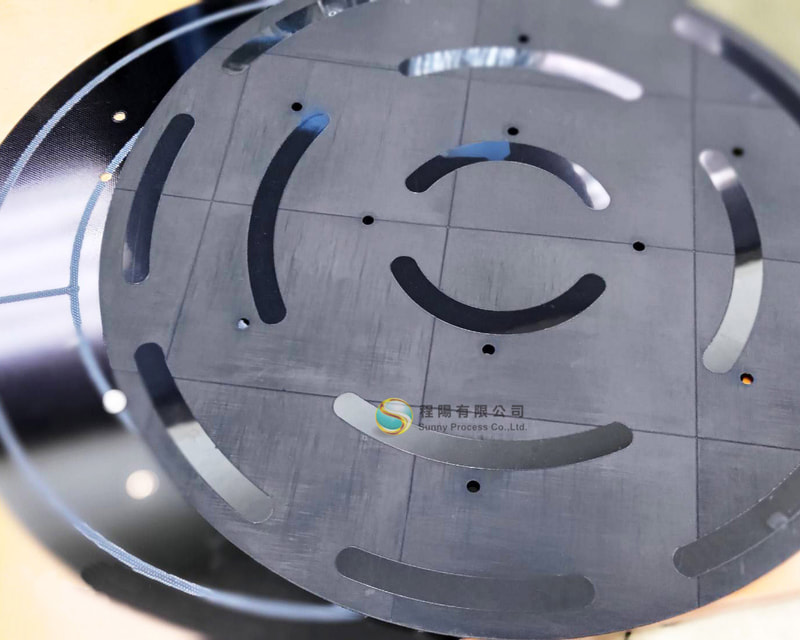

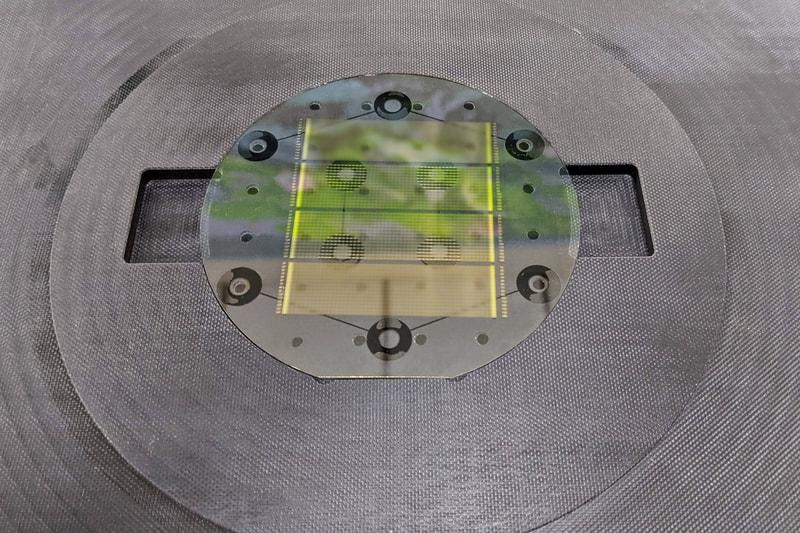

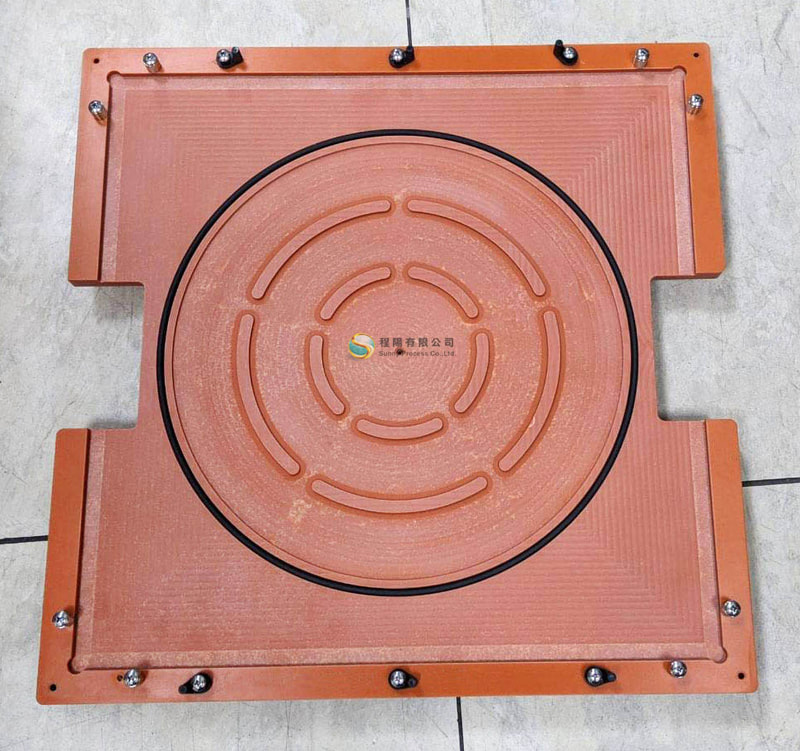

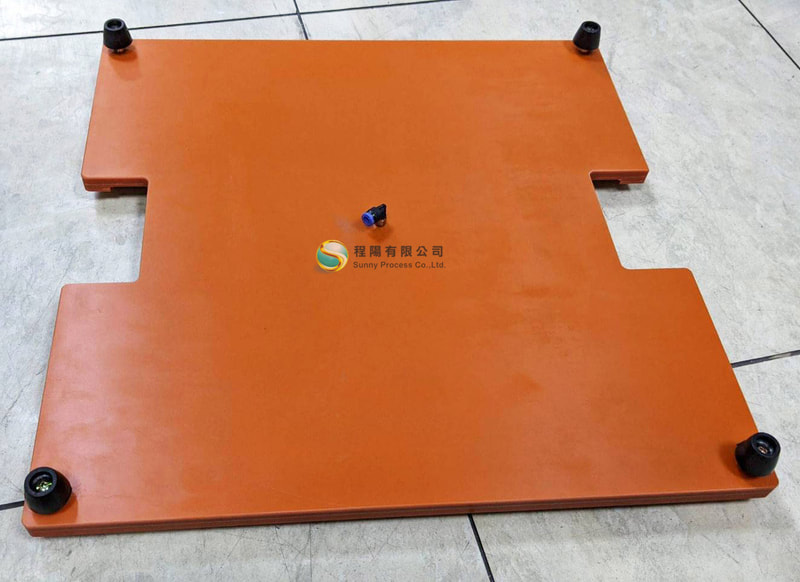

Glass Substrate / wafer applications

「SUNTABA vacuum pallets」complies with SGS's RoHS 2.0, PFOS, PFOA, and halogen-free environmental testing standards.

The use of carrier transport fixture with SUNTABA vacuum pallets enables glass substrate and wafer to be easily fixed, prevents breakage and deformation, and ensures safety when they are transferred and transported during the manufacturing processes.

The substrate can be fully supported by the carrier fixture during diebond printing and high-temperature processes, and will not be broken when separated, which is conducive to the completion of automated processes.

The substrate can be fully supported by the carrier fixture during diebond printing and high-temperature processes, and will not be broken when separated, which is conducive to the completion of automated processes.

|

|

|

| 貼霸®晶片轉移.pdf | |

| File Size: | 304 kb |

| File Type: | |