thermobstructor

「THERMOBSTRUCTOR」complies with SGS's RoHS 2.0, PFOS, PFOA, and halogen-free environmental testing standards.

| SGS測試-鍛熱霸™_2021.pdf | |

| File Size: | 421 kb |

| File Type: | |

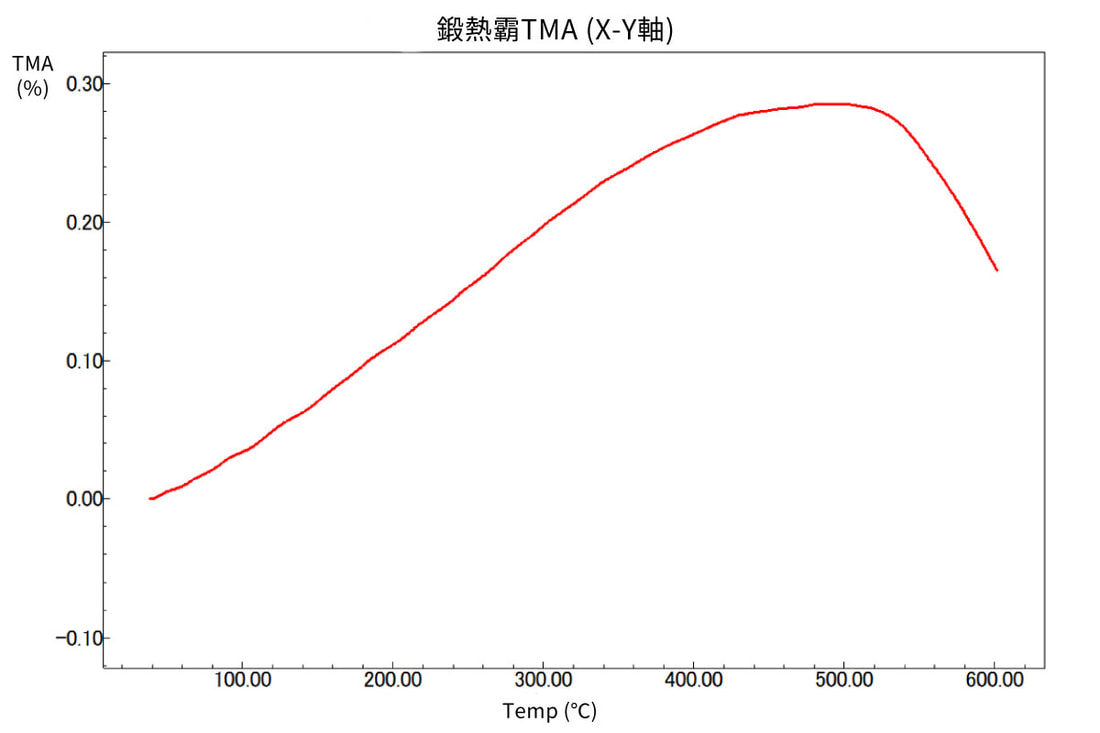

High temperature thermal insulation material that withstands up to 400 ° C.

It can stabilize the deformation caused by thermal expansion or high temperature pressure, and also control the deformation caused by continuous use.

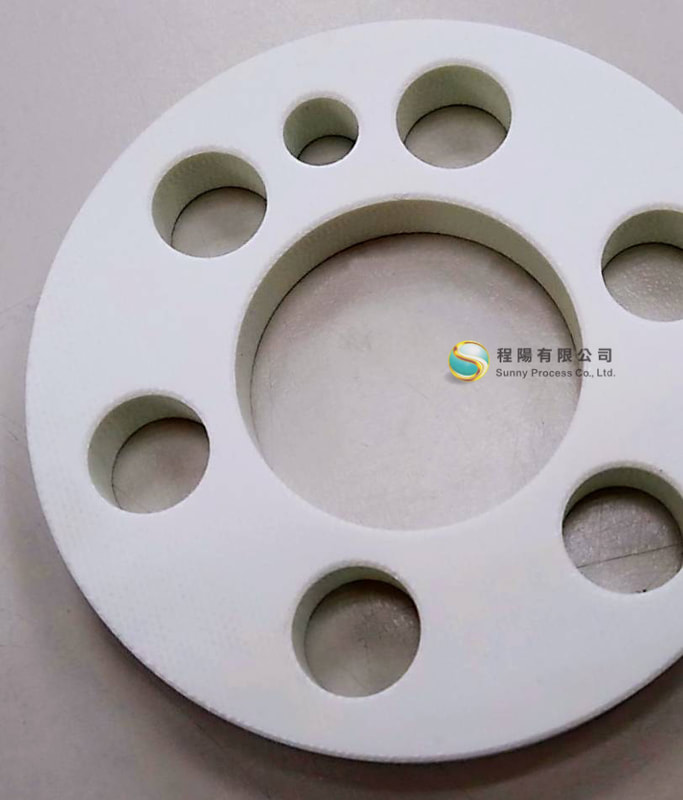

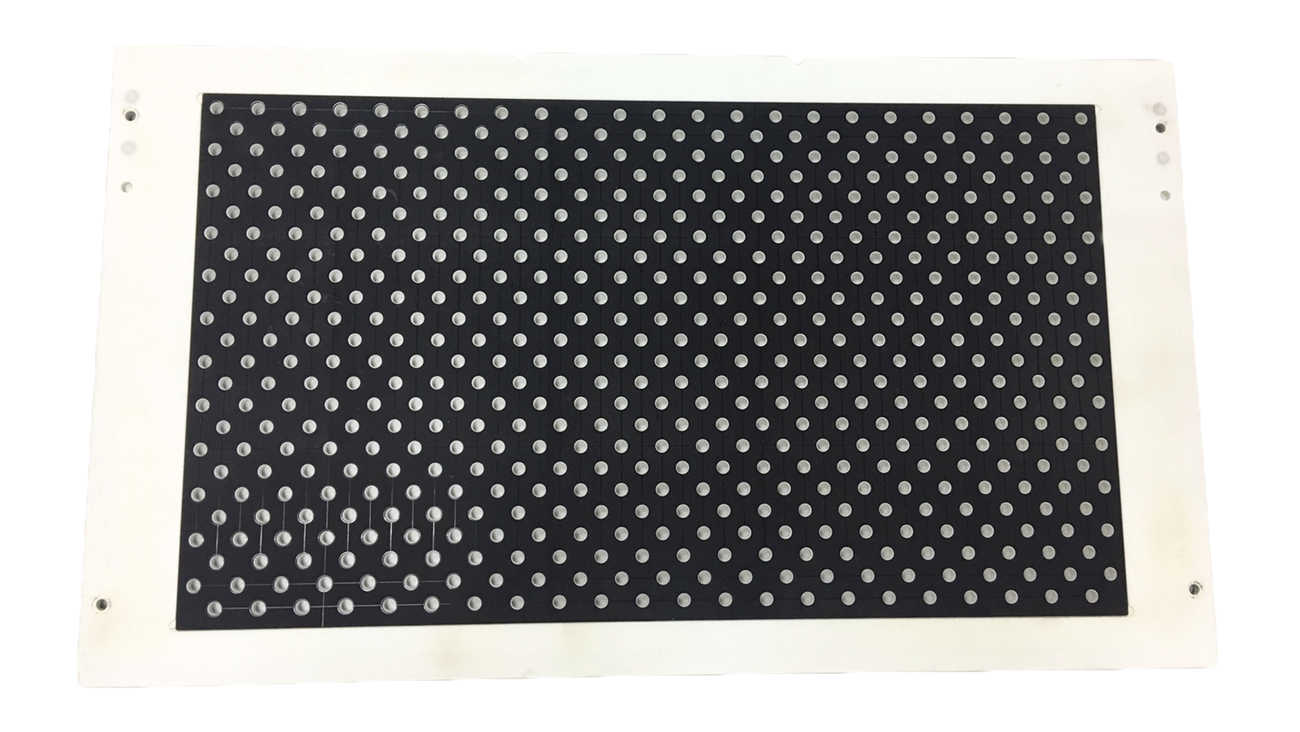

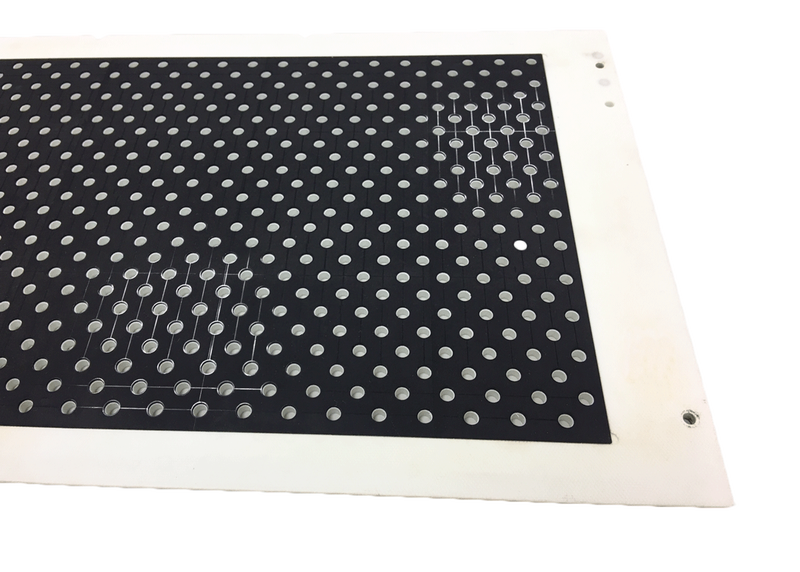

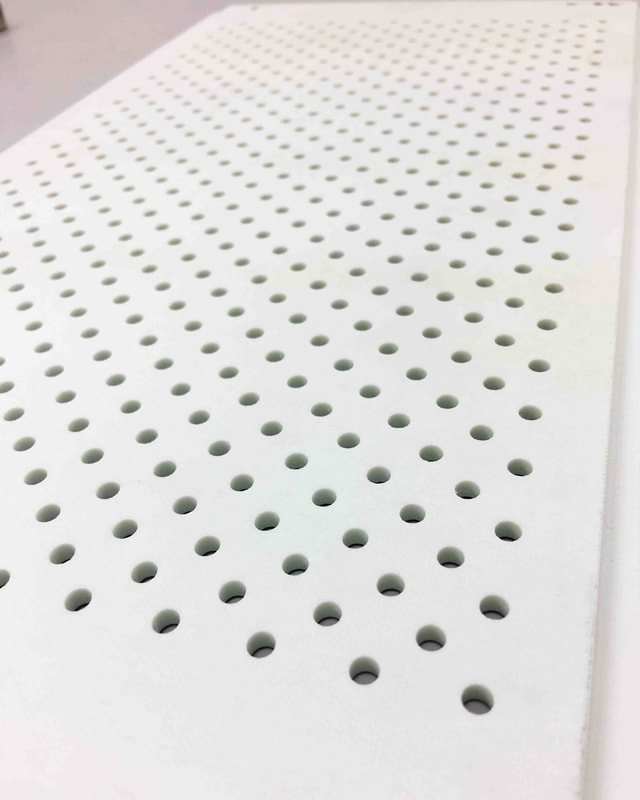

.Color:White

.Composition:Glass fiber cloth + inorganic resin. ※No asbestos is used for this material.

.Features:High temperature resistance up to 400 degrees, high dimensional stability, low water absorption, compression strength, good resistance to bending and deformation.

.Application:Applicable to heat insulation plates for molding machine, heat insulation plate for semiconductor sealing mold, heat insulation plate for induction heating oven, load bearing fixture for processing... etc.

.Machining recommendations: low speed high feed, 10mm~5mm tool, S2000, F500~F1000.

It can stabilize the deformation caused by thermal expansion or high temperature pressure, and also control the deformation caused by continuous use.

.Color:White

.Composition:Glass fiber cloth + inorganic resin. ※No asbestos is used for this material.

.Features:High temperature resistance up to 400 degrees, high dimensional stability, low water absorption, compression strength, good resistance to bending and deformation.

.Application:Applicable to heat insulation plates for molding machine, heat insulation plate for semiconductor sealing mold, heat insulation plate for induction heating oven, load bearing fixture for processing... etc.

.Machining recommendations: low speed high feed, 10mm~5mm tool, S2000, F500~F1000.

Features

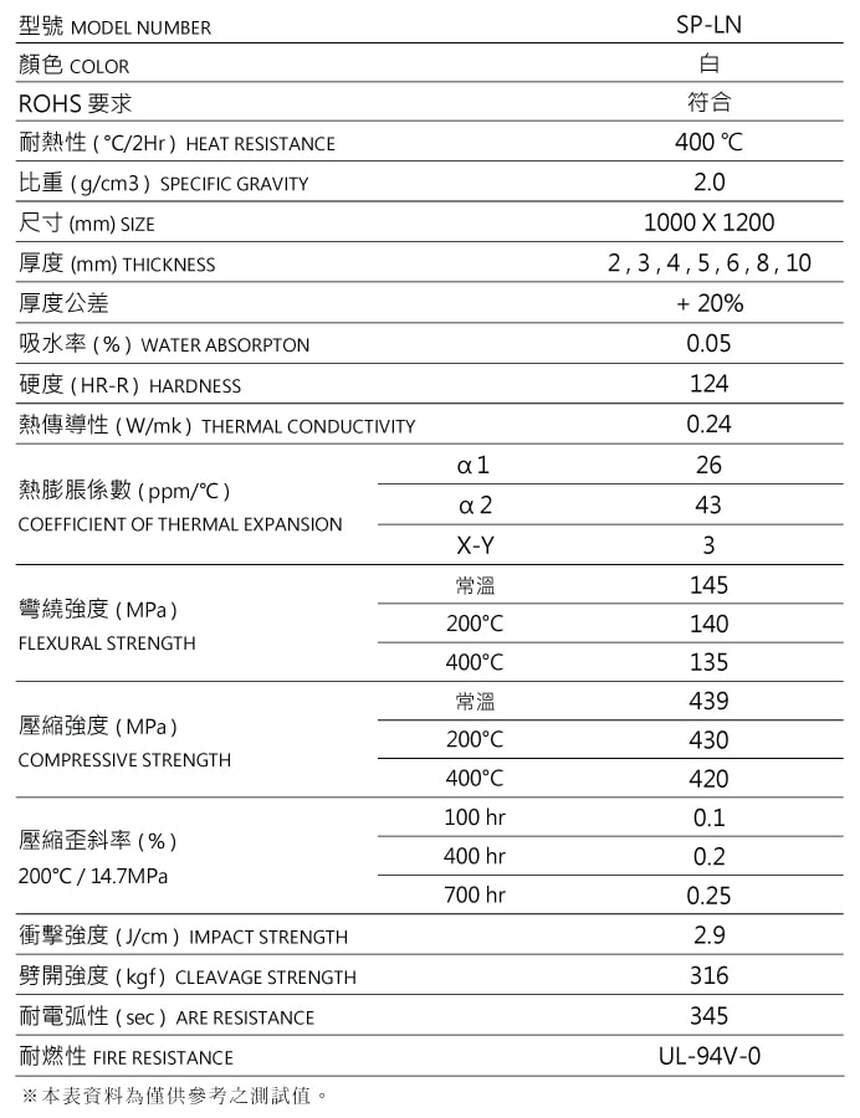

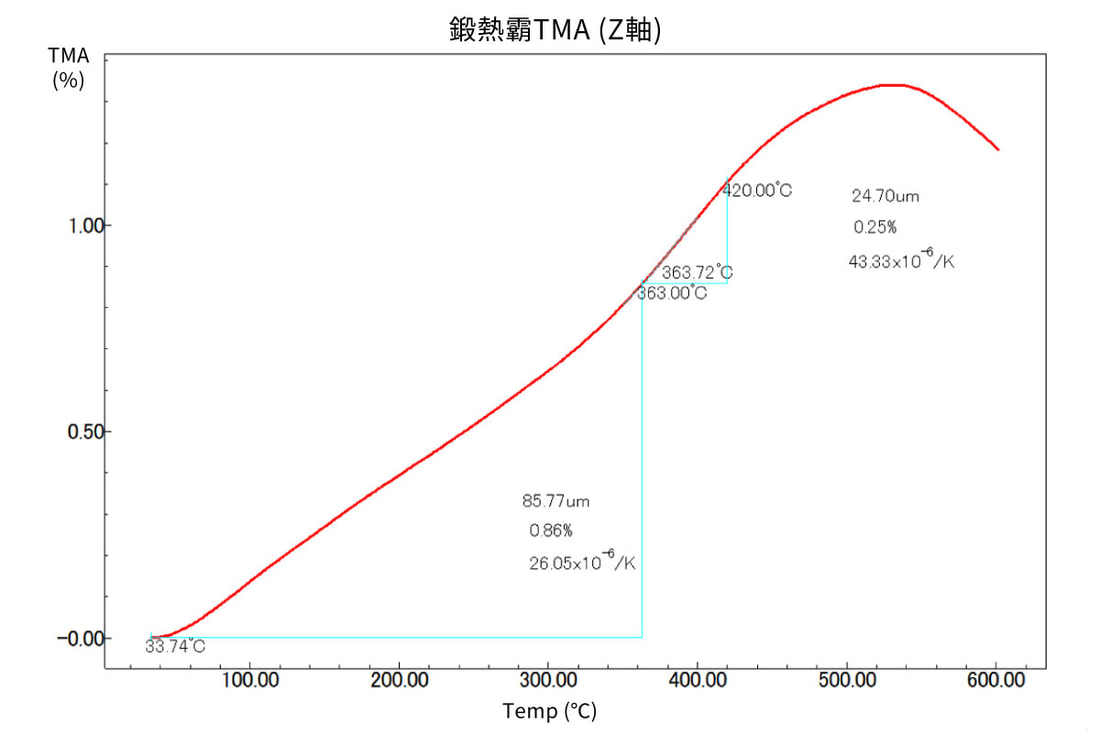

tma test

baking test

THERMOBSTRUCTOR After baking for 2 hours at 400°C, the deformation is 5.12 ~ 5.34mm and the weight is reduced by 0.536%.

(Tested material dimensions:5 x 418 x 240 mm)

(Tested material dimensions:5 x 418 x 240 mm)

|

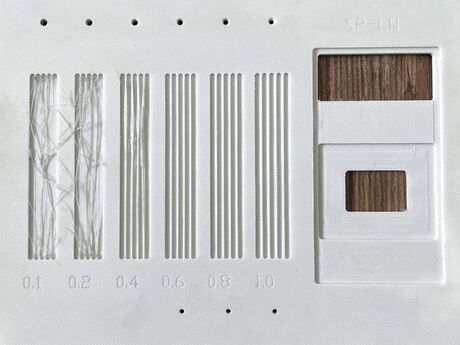

machining

Maching recommendations : Low speed, high feed、10mm~5mm tool、S2000、F500~F1000。

The thinnest vertical surface : 0.6 mm

Applicable tap : M3, M4

The thinnest vertical surface : 0.6 mm

Applicable tap : M3, M4