Home > SUNTABA vacuum pallets applications > Mini LED Process

Copyright: tailex47

MINI LED suntaba vacuum pALlEtS applications

「SUNTABA vacuum pallets」complies with SGS's RoHS 2.0, PFOS, PFOA, and halogen-free environmental testing standards.

Mini LED backlighting uses LED wafers that have reached the micron stage, and there are usually thousands of tiny pads on the Mini LED substrate.

Such a large number of solder joints and the level of precision required make the wafer assembly much more difficult and also makes the substrate more prone to warpage after the high temperature of the reflow oven due to the thinness of the board.

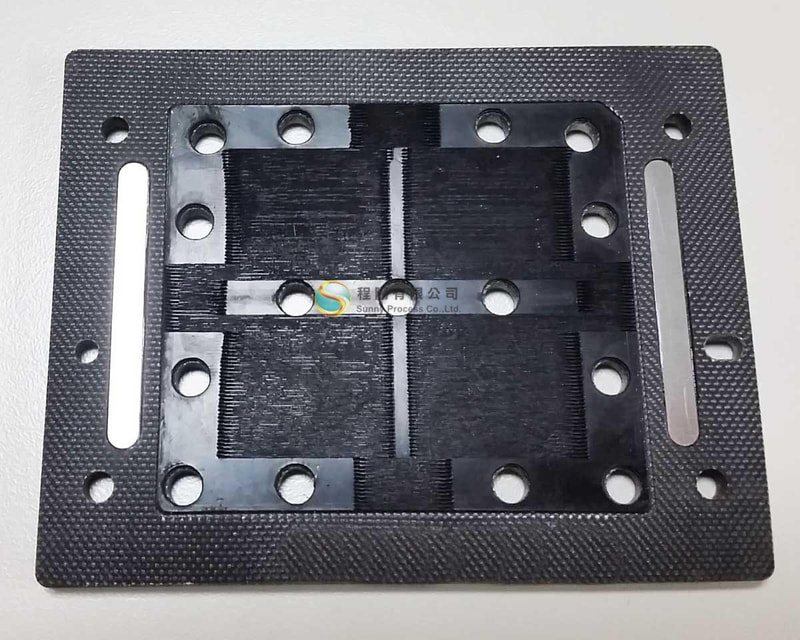

Compared to the current SMT printing process, Mini LED require higher printing precision.

For Mini LED, the thin substrate printing technology, the thickness of the steel plate (below 0.05mm), and the diebond full-process fixtures all require higher precision and lower CTE of the material.

In Mini LED assembly, there are processes such as printing, solder paste inspection, placement, reflow soldering, automatic visual inspection, dispensing and baking...etc. The thinner the board, the more "high performance materials" combined with "high precision" carriers are required to complete these processes.

In the past, tape was used to fix the position of the substrate to ensure no displacement in the aforementioned part of the process, but it cannot meet the current manufacturing process applications of Mini LED. Gactors include disadvantages such as the uncertainty of fixing around or at the bottom of the substrate, the thickness of the tape interfering with the print quality, the labor consumption, and the inability to enter automatic production.

In view of the above disadvantages, Sunny Process has developed the SUNTABA vacuum pallets for use in the mini LED manufacturing process, which can:

Such a large number of solder joints and the level of precision required make the wafer assembly much more difficult and also makes the substrate more prone to warpage after the high temperature of the reflow oven due to the thinness of the board.

Compared to the current SMT printing process, Mini LED require higher printing precision.

For Mini LED, the thin substrate printing technology, the thickness of the steel plate (below 0.05mm), and the diebond full-process fixtures all require higher precision and lower CTE of the material.

In Mini LED assembly, there are processes such as printing, solder paste inspection, placement, reflow soldering, automatic visual inspection, dispensing and baking...etc. The thinner the board, the more "high performance materials" combined with "high precision" carriers are required to complete these processes.

In the past, tape was used to fix the position of the substrate to ensure no displacement in the aforementioned part of the process, but it cannot meet the current manufacturing process applications of Mini LED. Gactors include disadvantages such as the uncertainty of fixing around or at the bottom of the substrate, the thickness of the tape interfering with the print quality, the labor consumption, and the inability to enter automatic production.

In view of the above disadvantages, Sunny Process has developed the SUNTABA vacuum pallets for use in the mini LED manufacturing process, which can:

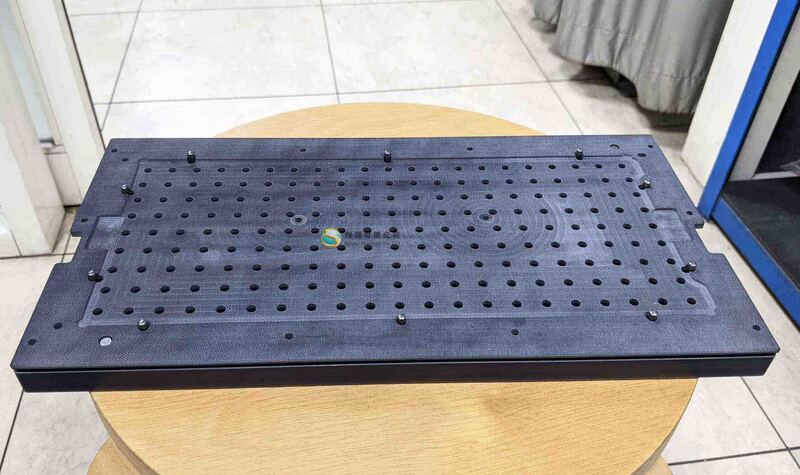

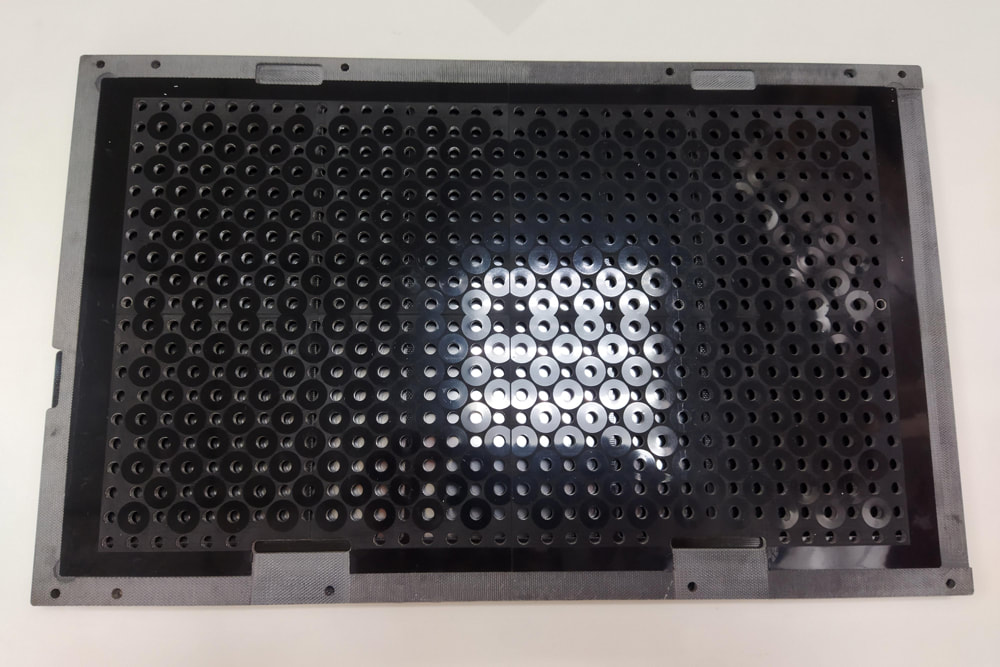

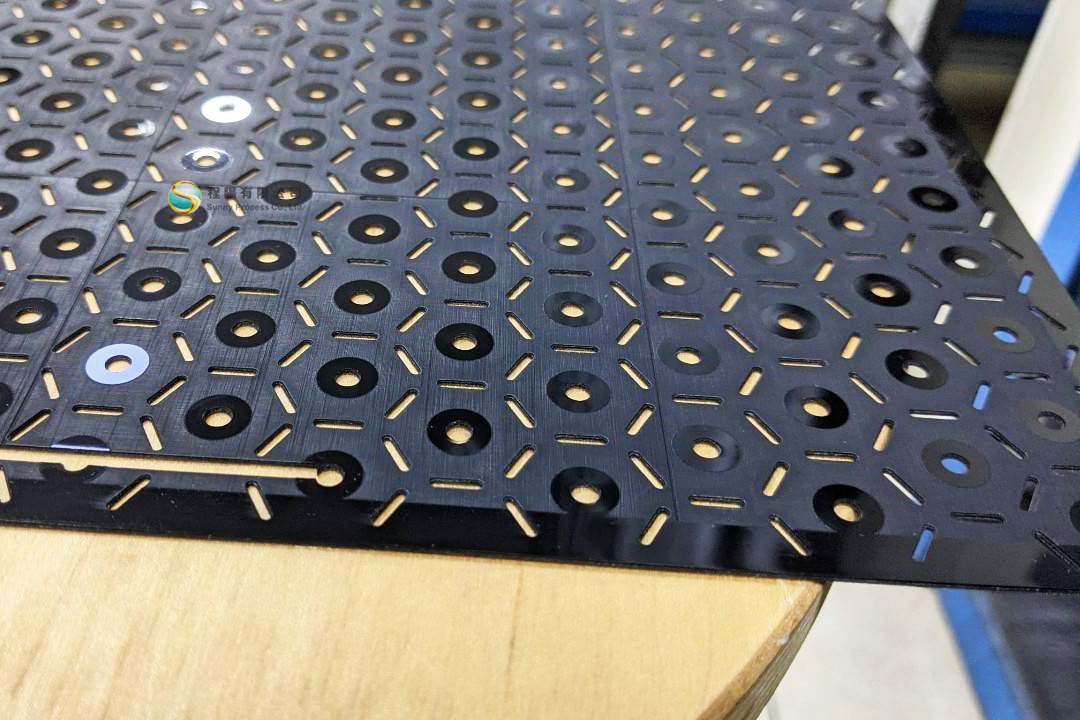

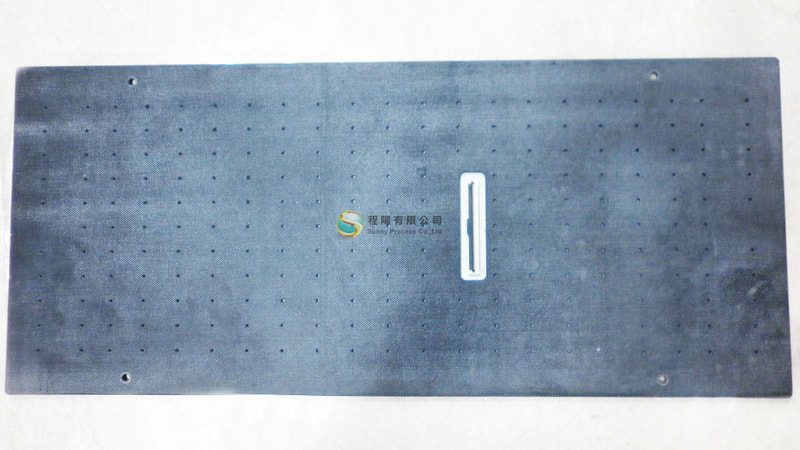

- Adsorb and fix thin FPC and PCB without applying and removing adhesive tapes.

- Control adhesion force for precise and flat adhesion.

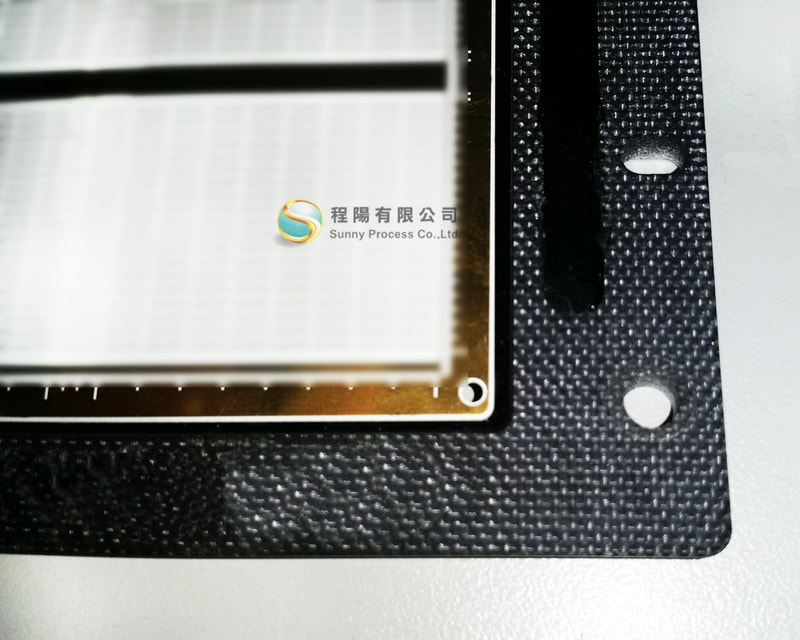

- Technologies for fixing into position the underside of circuit boards to ensure no interfere with the printing thickness, reduces the printing variables, and facilitates the overall flatness of the substrate.

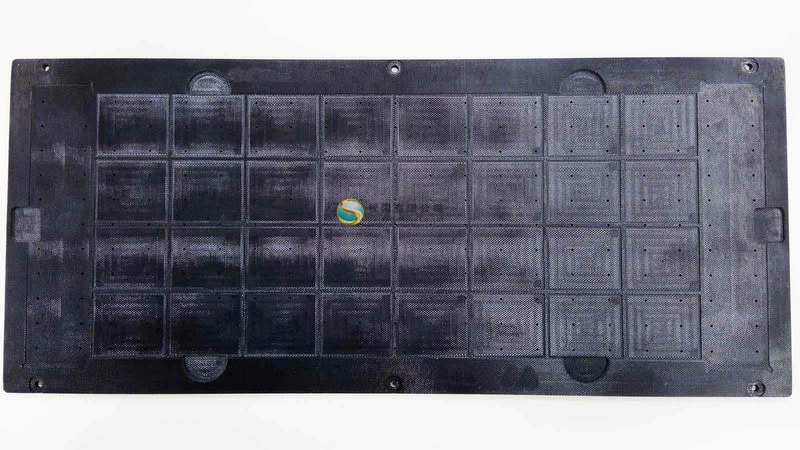

- Additional frame design eliminates scraper vibration during printing.

- High temperature resistance, reusable, and no tape use for increased environmental friendliness and cost efficiency.

- Auto-adsorption can be used for fully automatic production line operations.

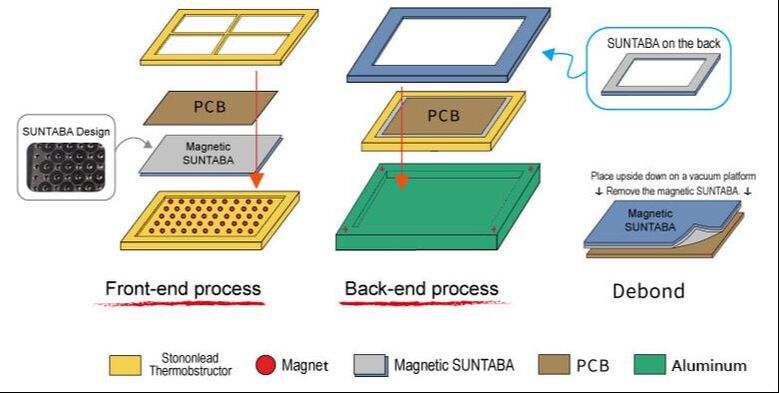

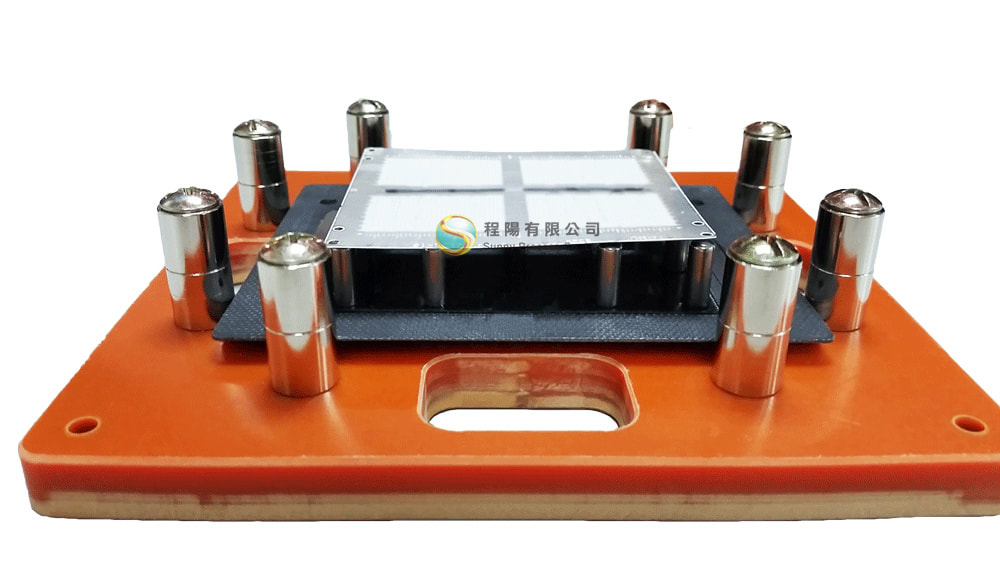

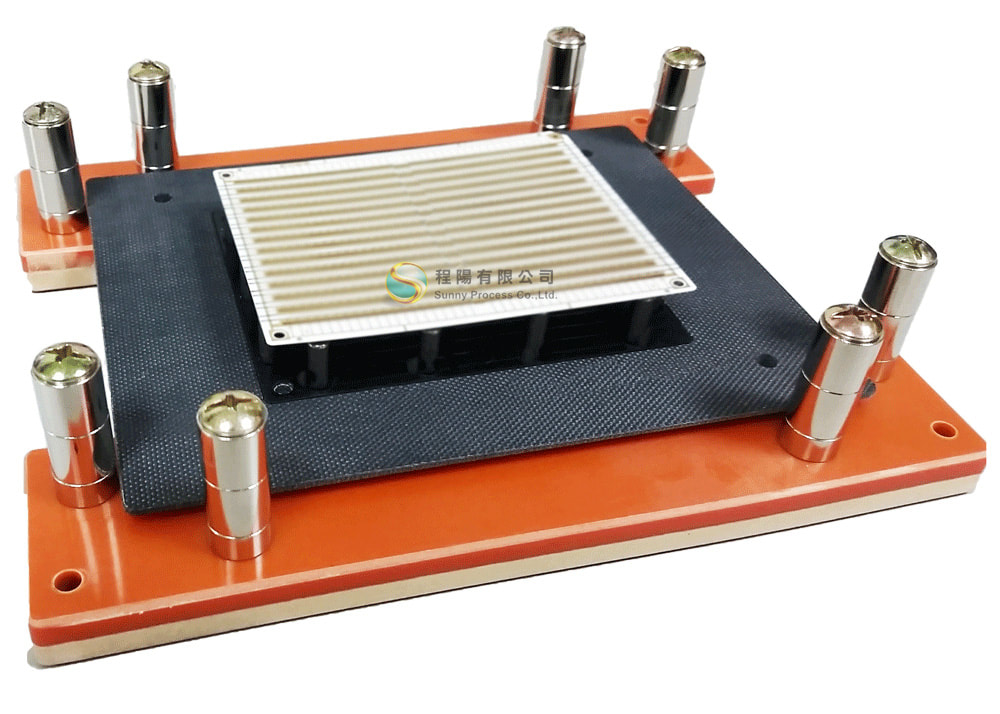

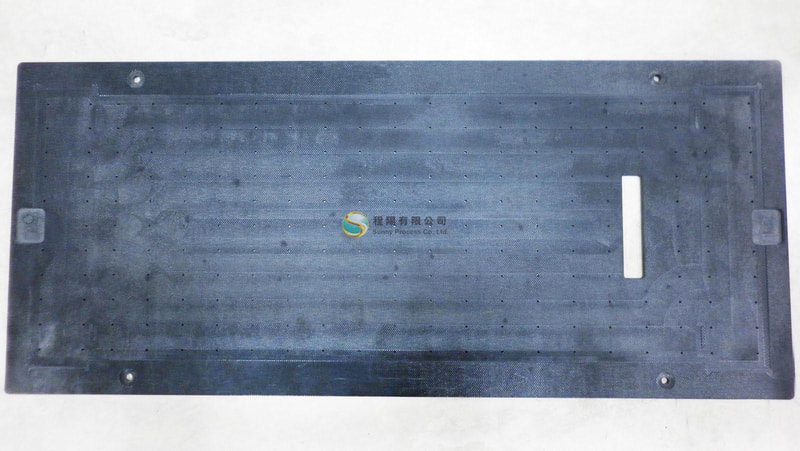

SUNTABA VACUUM MAGNETIC PALLETS

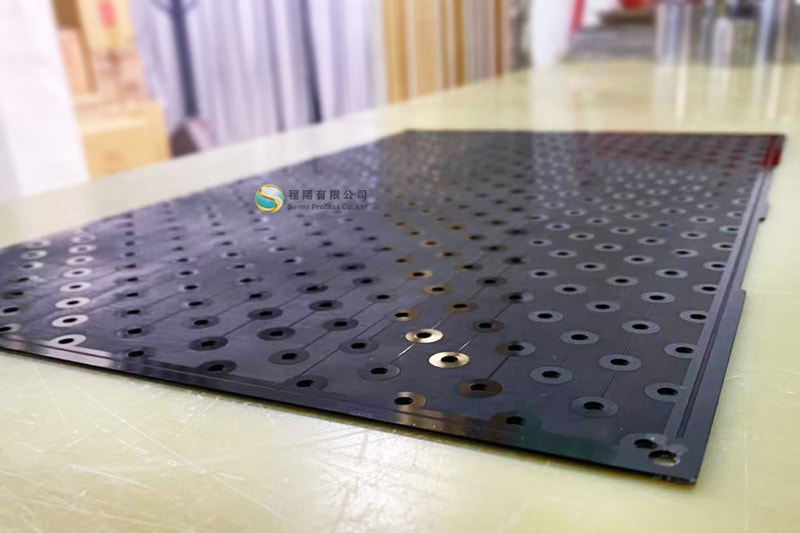

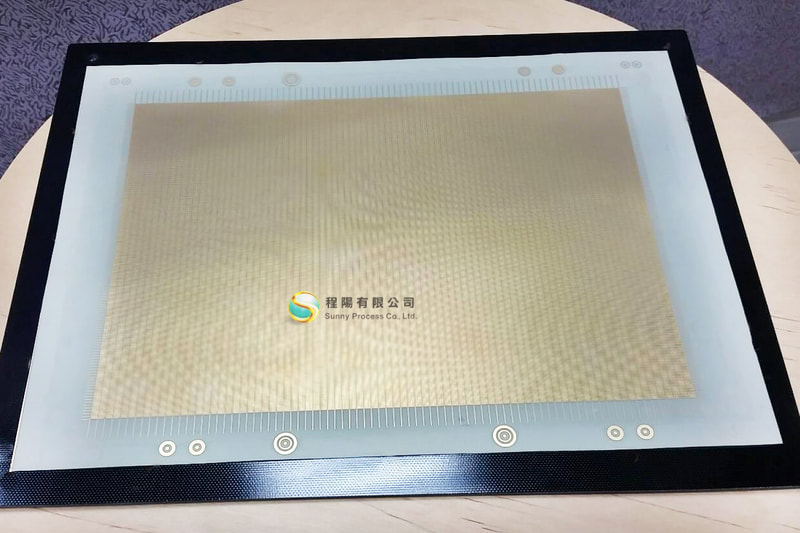

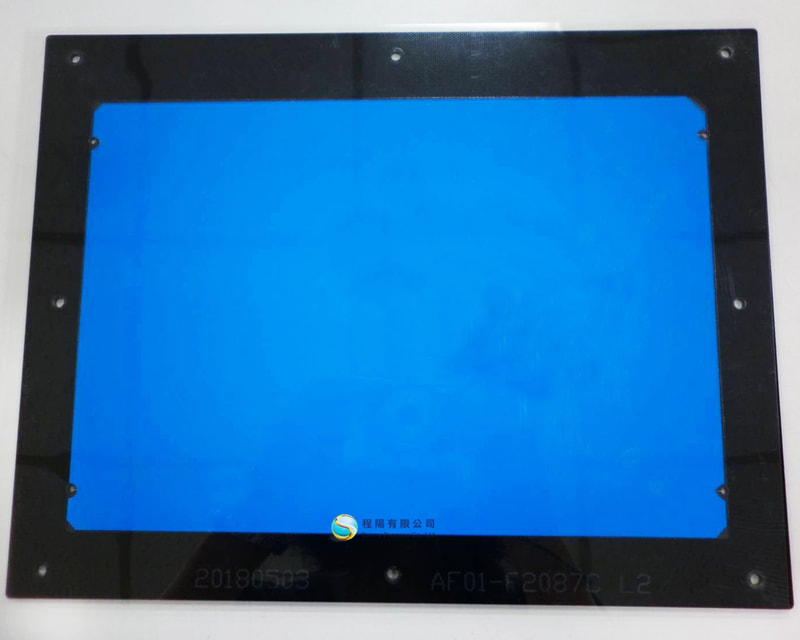

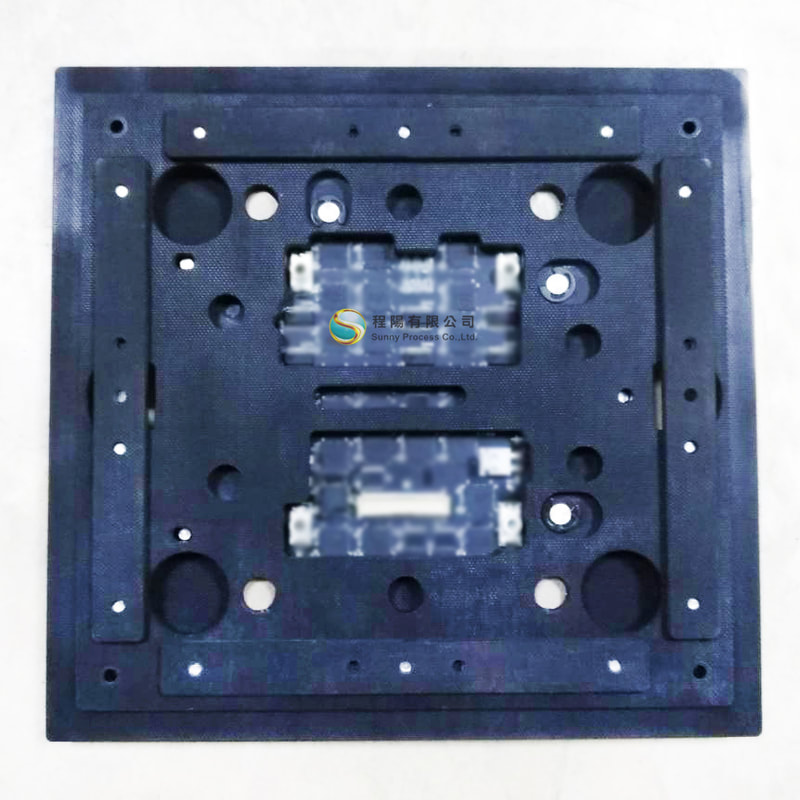

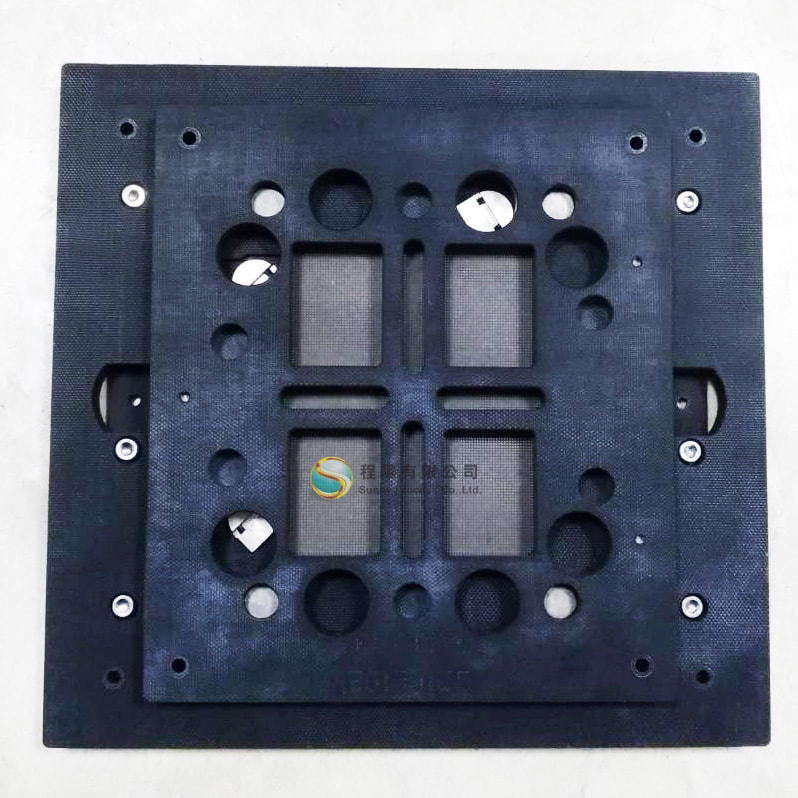

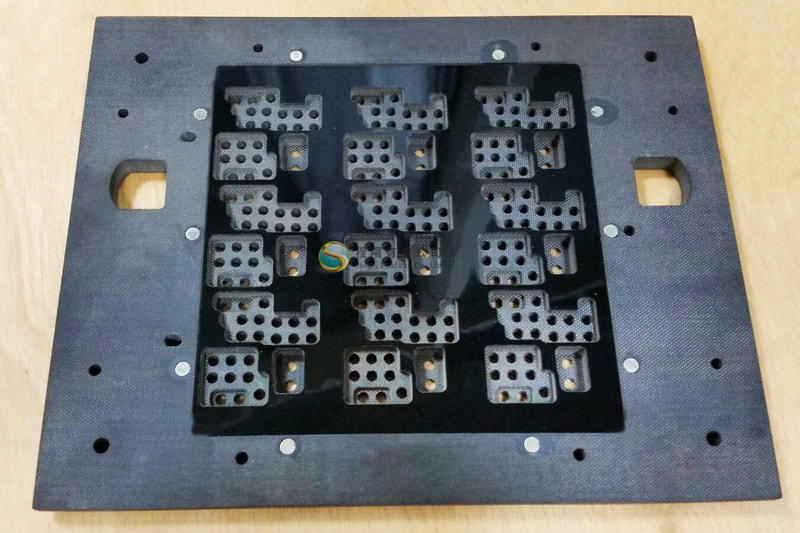

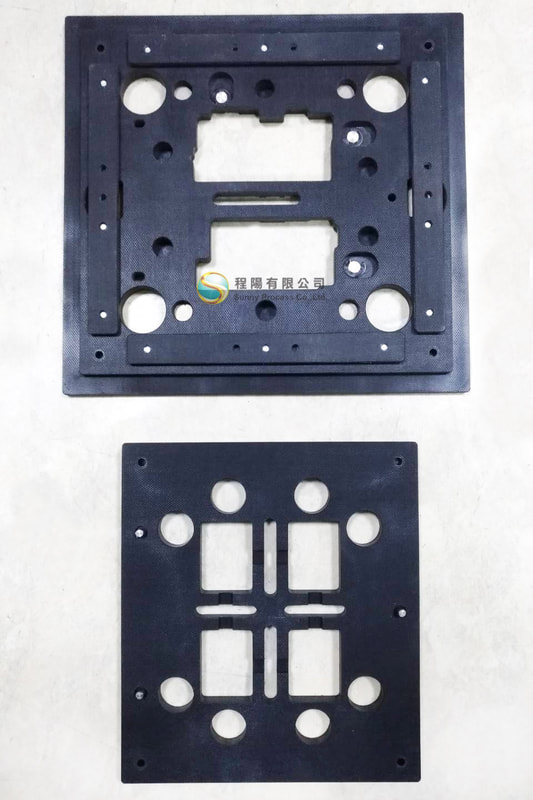

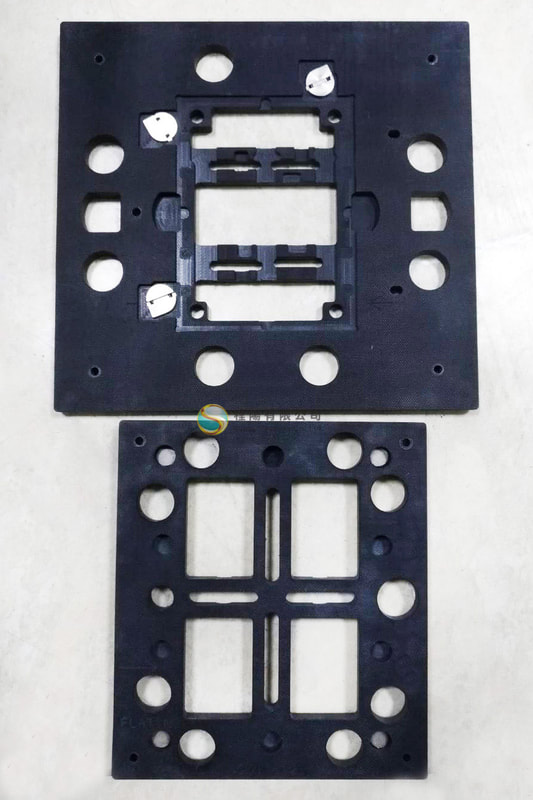

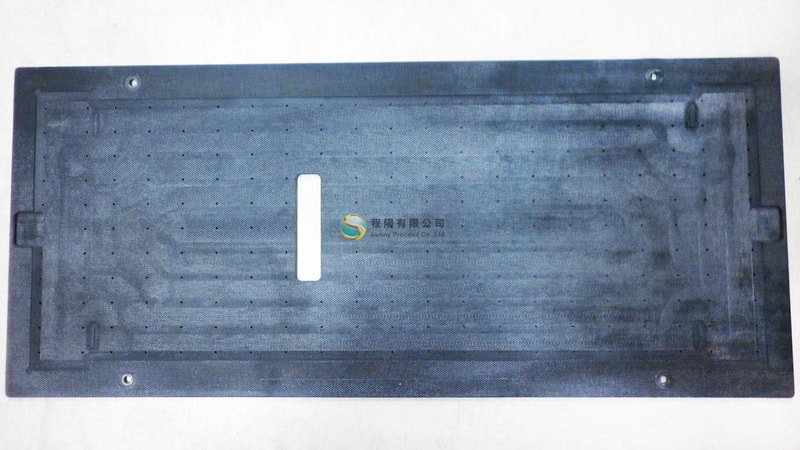

Due to the requirement of equipment and various production conditions, the carrier must feature all required functions such as flatness, high temperature resistance, prevention of substrate deformation, easy separation, and reuse, etc. Sunny Process has developed the SUNTABA vacuum magnetic plate to help resolve production problems and improve efficiency and yield.

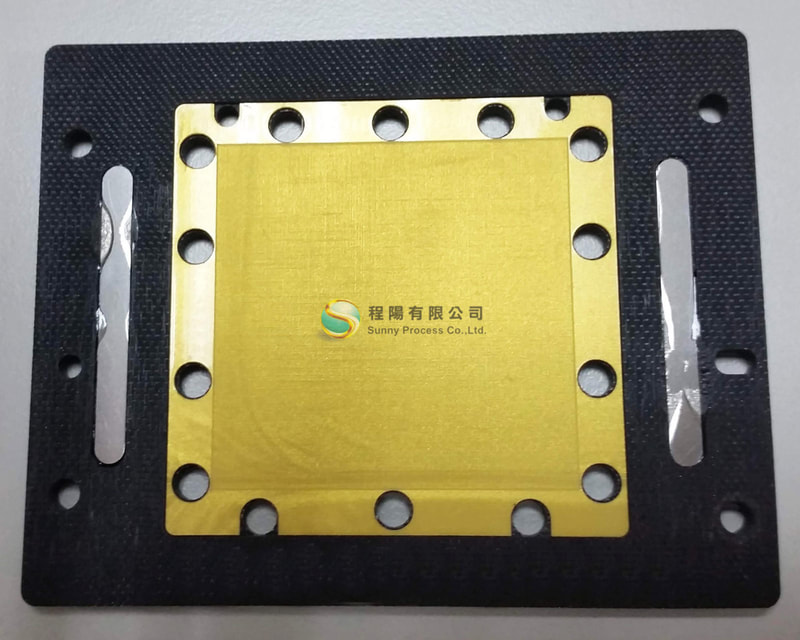

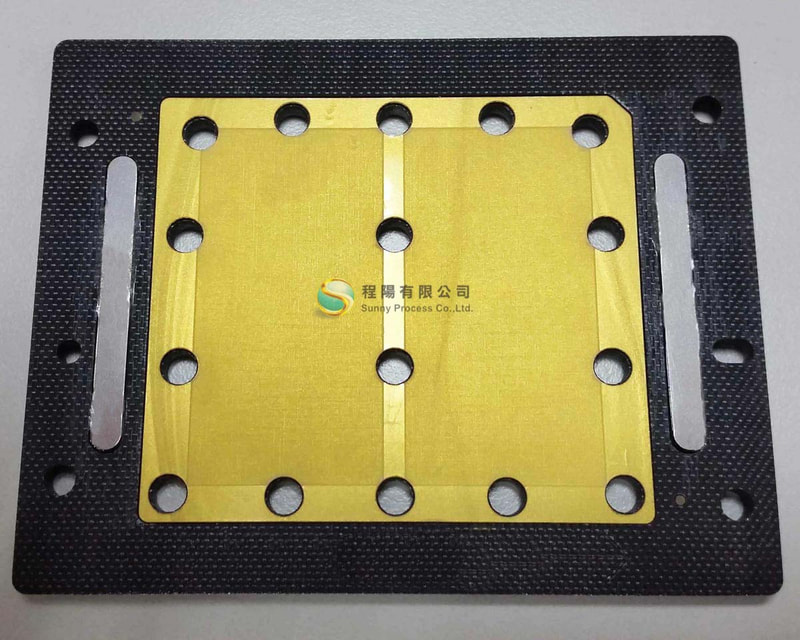

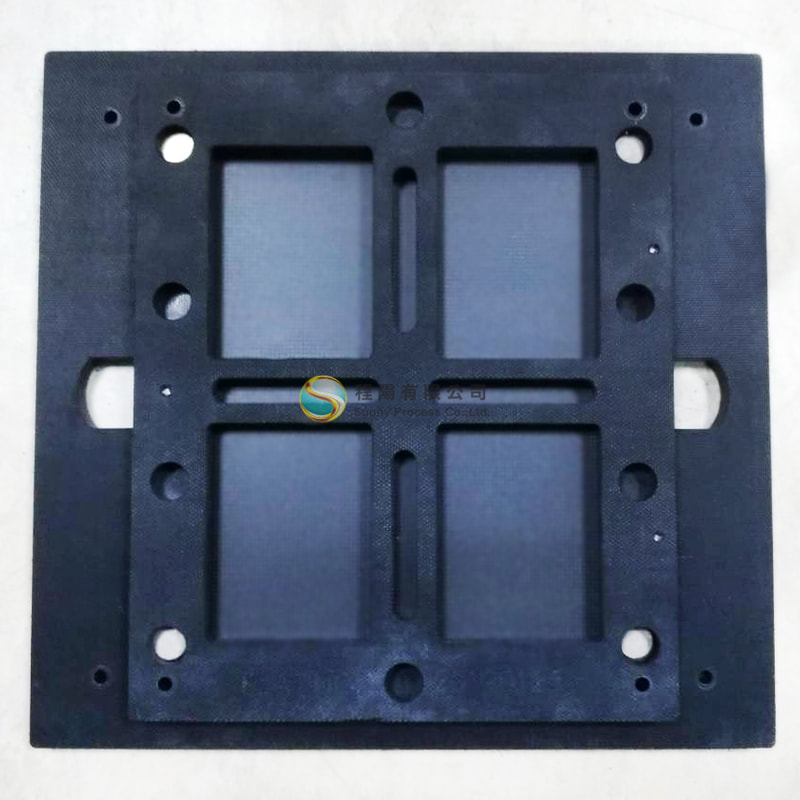

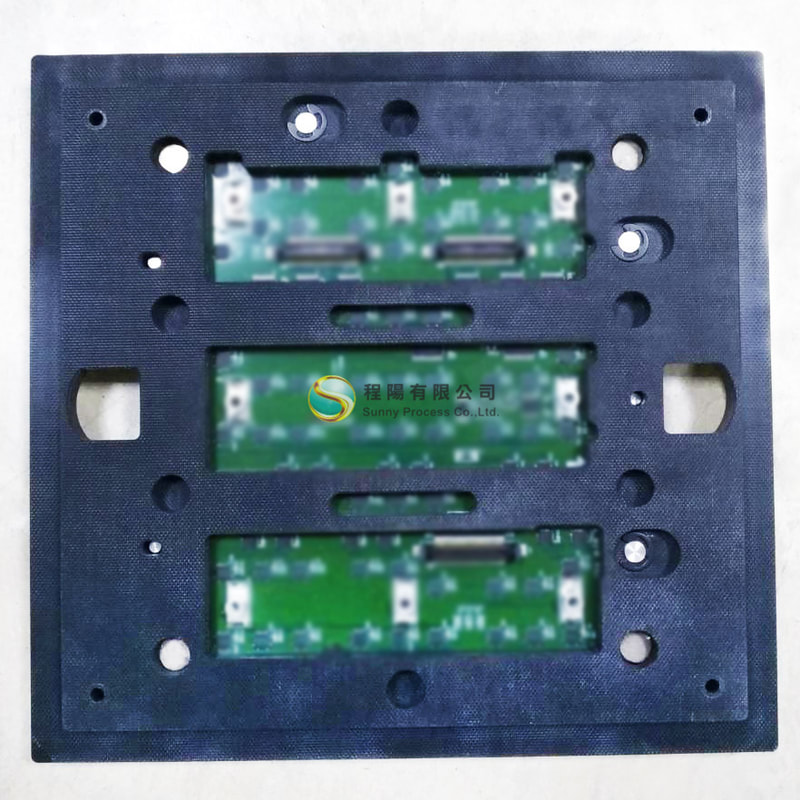

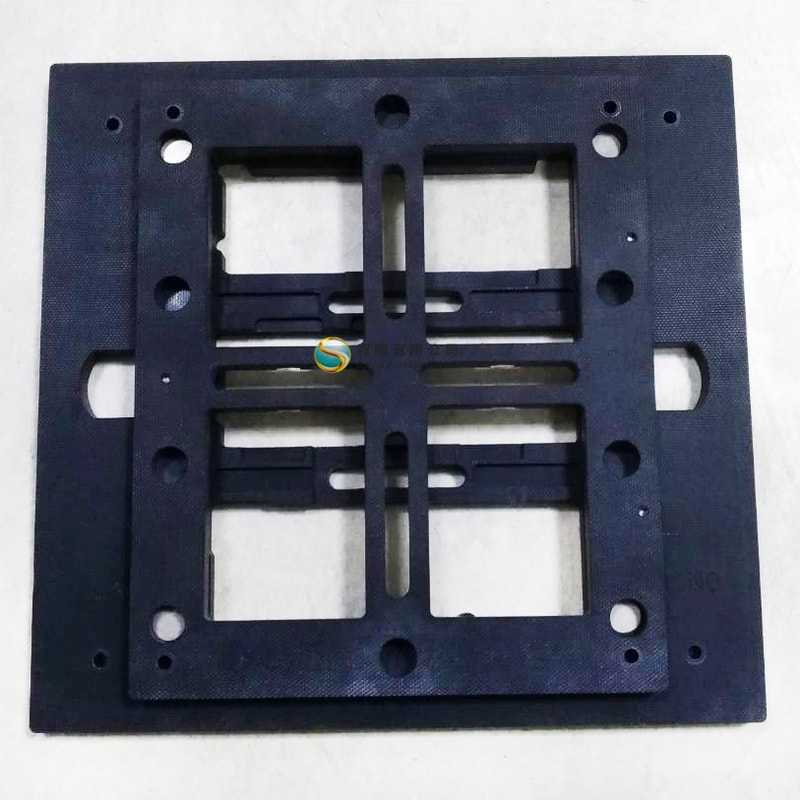

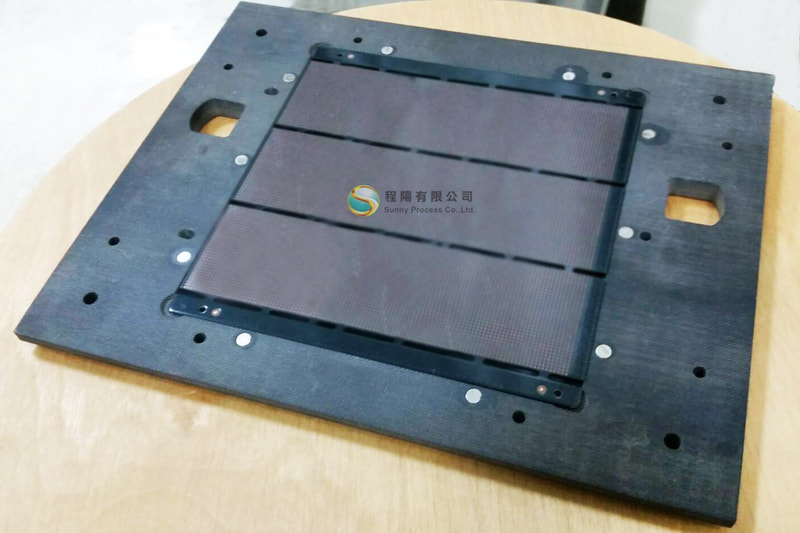

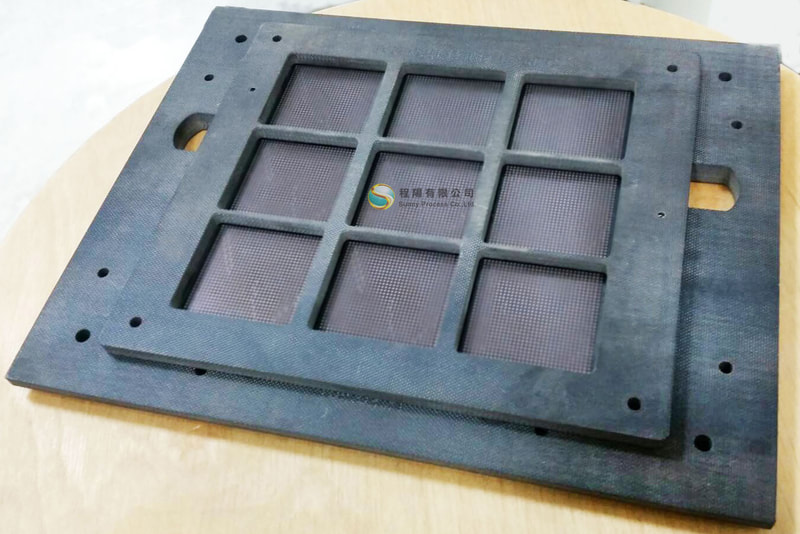

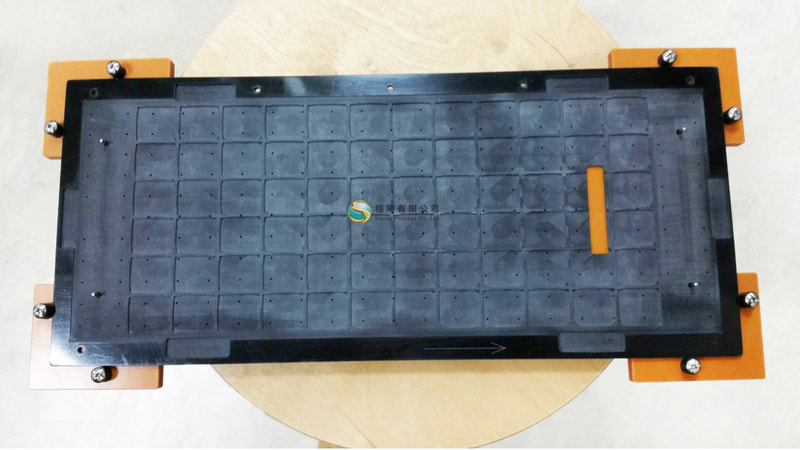

↑↑ SUNTABA vacuum magnetic pallets -- front-end process ↑↑

Applications

|

|