SMT

SMT (Surface Mounting Technology) is a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of printed circuit boards (PCBs). The main steps are printing --> placement --> reflow soldering --> inspection.

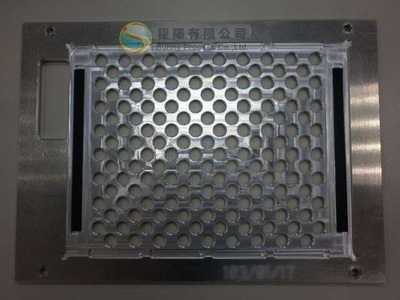

Following are the main functions by using the SMT fixture in the aforesaid process steps:

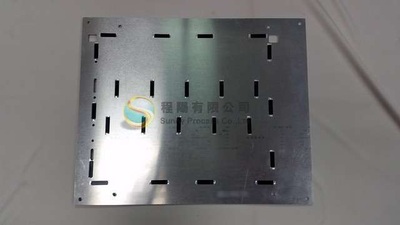

Traditionally, the aluminum alloy is used for fabricating the SMT fixture. The advantages of aluminum alloy are tooling easier and better cleanliness. But the following issues must be addressed when used in large quantityies:

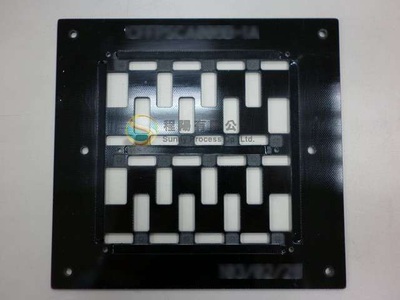

When encountering the aforesaid problem, it is suggested that you may use Stononlead® + SUNTABA for making improvements.

Following are the main functions by using the SMT fixture in the aforesaid process steps:

- Maintain the circuit board on a flat status and hold it in position during the printing process.

- Through the rigidity of the fixture, the stability of the placement can be improves, during the placement process.

- Keep the circuit board on a flat status during the reflow soldering process, to reduce the deformation after the soldering. (By using with the TieBar®, it helps to increase the production detect-free rate and improve the efficiency.)

- Guided into the AOI directly for carrying out automated quality inspection.

Traditionally, the aluminum alloy is used for fabricating the SMT fixture. The advantages of aluminum alloy are tooling easier and better cleanliness. But the following issues must be addressed when used in large quantityies:

- The aluminum alloy is a malleable material, it may present local damage or deformation due to the hitting and squeezing after several rounds of running. Then resulting in a decline in overall production detect-free rate.

- The thermal conductivity of aluminum alloy is about 237 Wm-1k-1. It means that most of the thermal energies will be absorbed by aluminum alloy during the reflow soldering process. To achieve satisfactory reflow soldering temperature on the circuit board, one would need to increase the soldering temperature, thus caused waste the energy. In the meantime, some of the electronic components may get damaged due to the temperature being so high and the deformation range of the circuit board will expand as well.

When encountering the aforesaid problem, it is suggested that you may use Stononlead® + SUNTABA for making improvements.